In Stockach, right on the picturesque Lake Constance in southern Germany, Kammerer MedTec GmbH has its headquarters and sustainable production department. The company manufactures medical devices for the knee, hip and spine. To do so, it has a modern machine park, of which CNC automation is also a crucial part. Indeed, since 2019, Kammerer has had four systems from RoboJob. "And our employees enjoy working with them immensely," says Christopher Kammerer, Managing Director of Kammerer Medical Group.

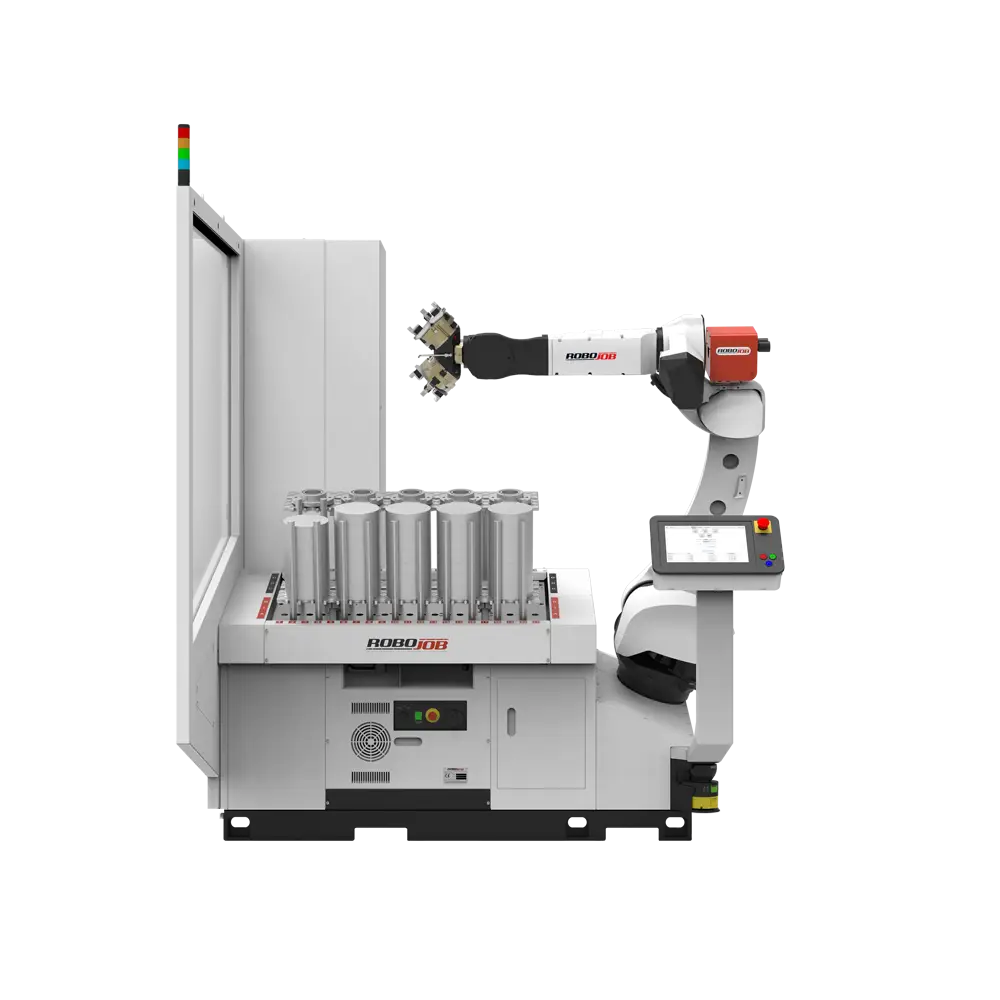

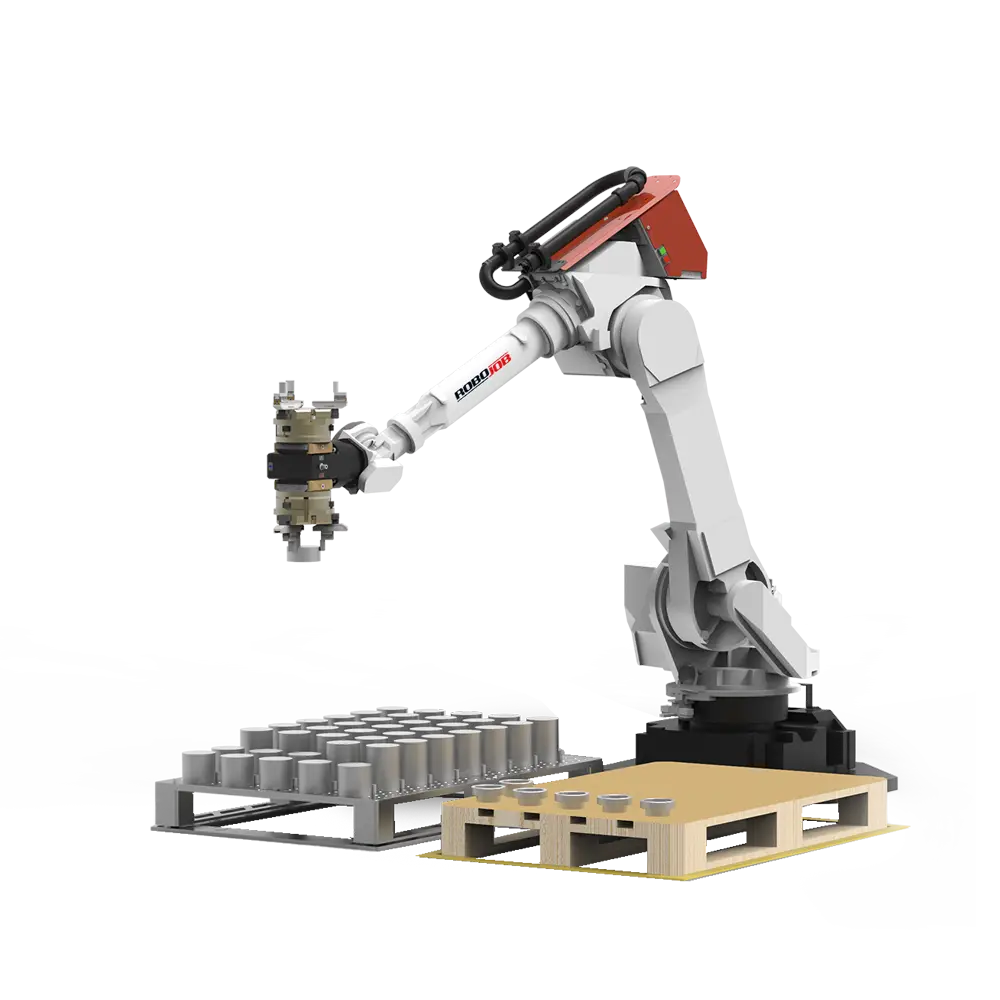

Besides 3 Turn-Assist models, which are all set up on Mazak Integrex Multi-tasking machines, Kammerer also opted for RoboJob's Pallet-Load: this is a very simple automation concept that can be used to automate turning machines, milling machines as well as turning/milling combinations. One or more pallets are set up and a robot loads the materials directly into the CNC machine; finished parts are deposited back onto the pallets. To ensure accurate positioning, the raw workpieces are placed on an aluminium pallet that the customer can configure himself according to the workpiece dimensions.

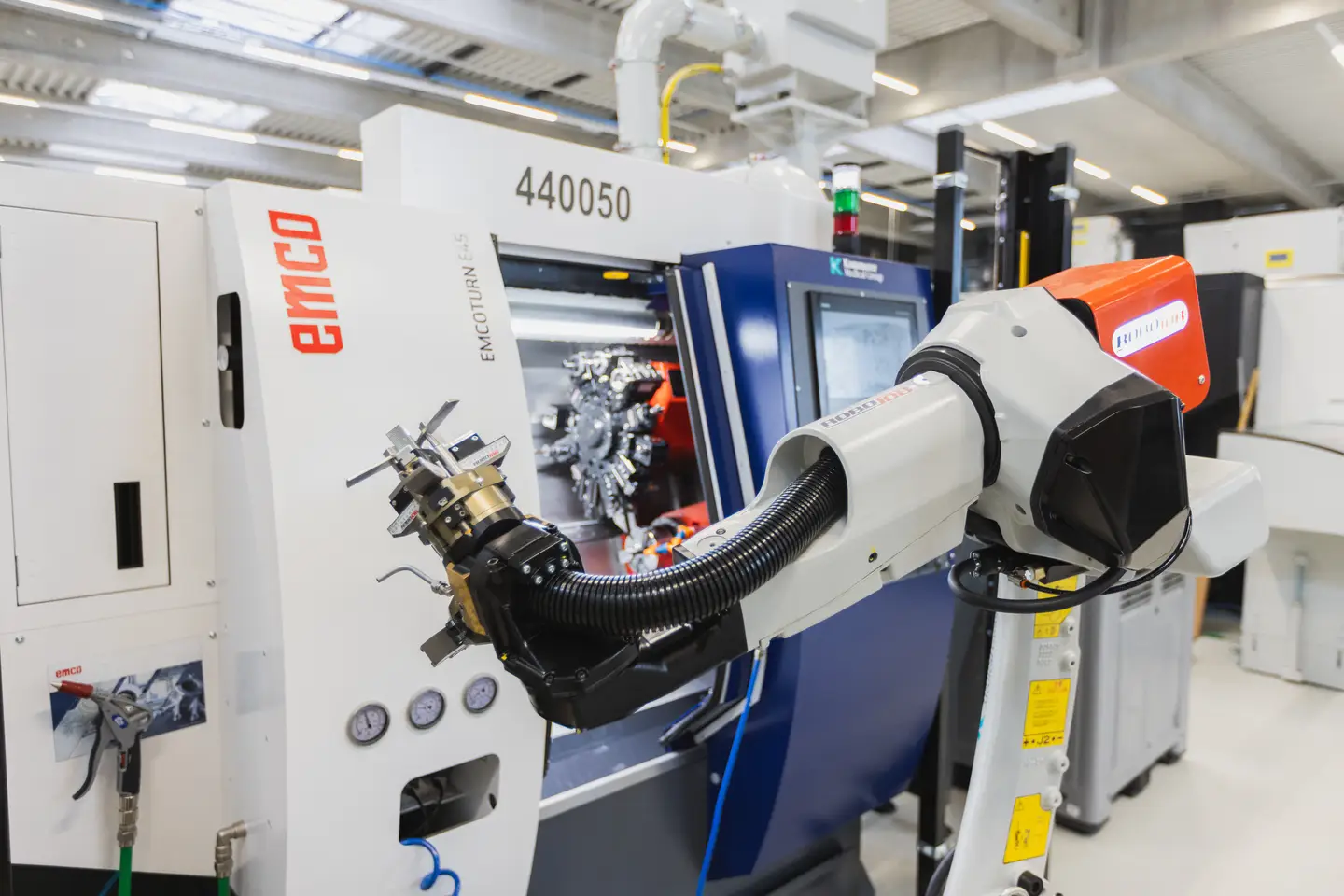

"We chose Pallet-Load automation because of the simplicity of this solution," Kammerer testifies. "We have previously experienced how smoothly and easily the installation of the Turn-Assist models on our Mazak machines went, and the installation of the Pallet-Load on our Emco E45 also went extremely smoothly."

"Our production is even more flexible than without automation because we can quickly process unexpected orders. Without long set-up times or increasing the workload of our operators."

"We have been familiar with RoboJob since 2019. Both the Turn-Assist models and this Pallet-Load are extremely easy to use on a daily basis. We have been able to further optimise the latter system together so that we can get the maximum efficiency out of our machine. Thanks to RoboJob's automations, we manage to produce 6 days a week, 24 hours a day," Kammerer said.

"RoboJob has proved to be a good investment not only financially, but also for our employees who enjoy working with it because it is so easy to operate. Moreover, our production is even more flexible than without automation because we can quickly process unexpected orders. Without long set-up times or increasing the workload of our operators. I could recommend RoboJob to anyone because of its value for money and ease of use for the operator."