Your journey to CNC Automation starts here

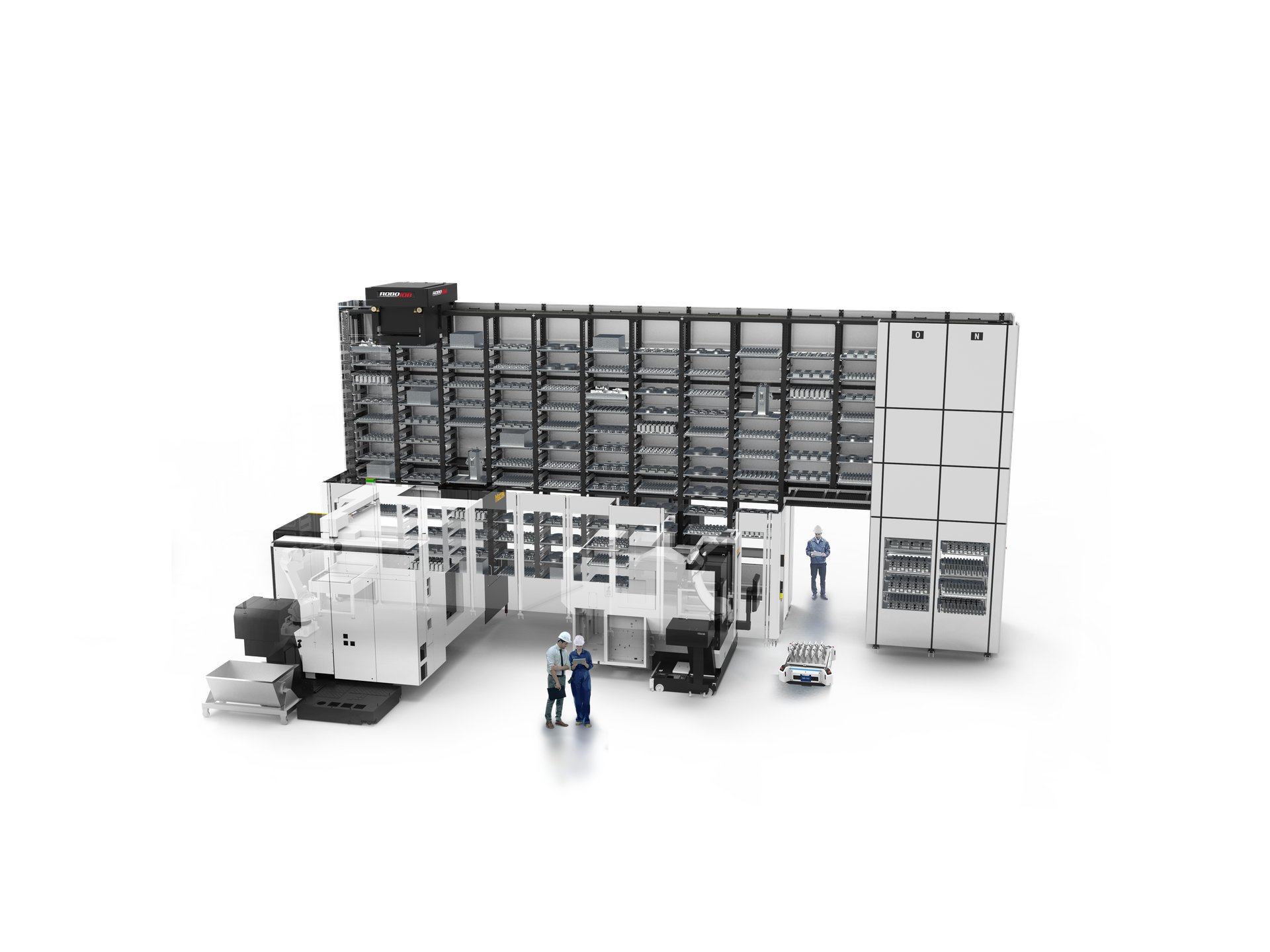

Automating CNC machines, that's what we do at RoboJob. Since 2007 already, we’ve been setting the standard with user-friendly, off-the-shelf automation solutions designed to boost efficiency and flexibility in manufacturing.

With more than 2,000 robots installed worldwide, our expertise is unmatched.

Our mission goes beyond automation. We aim to make manufacturing more appealing for the next generation because, without people, there is no industry. By automating repetitive tasks, we not only free up operators but also ensure CNC machines maximize spindle hours, keeping them profitable - and keeping our industry strong.

Why automate?

These principles are the founding reasons for RoboJob, and it's remarkable that they are still as relevant today as they were 18 years ago. As market leader we are here for the entire industry: whether you are aware of these reasons to automate, or whether this is the first time you're reading them.

How do we Automate?

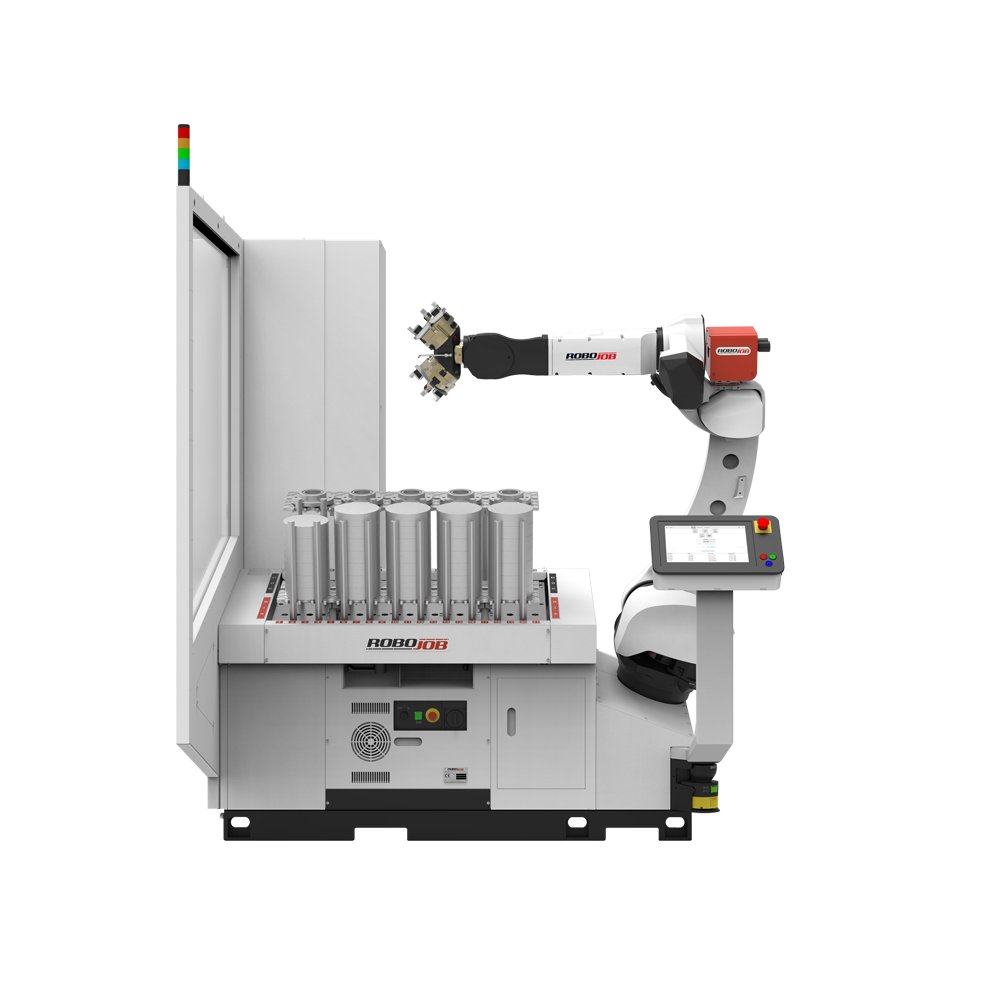

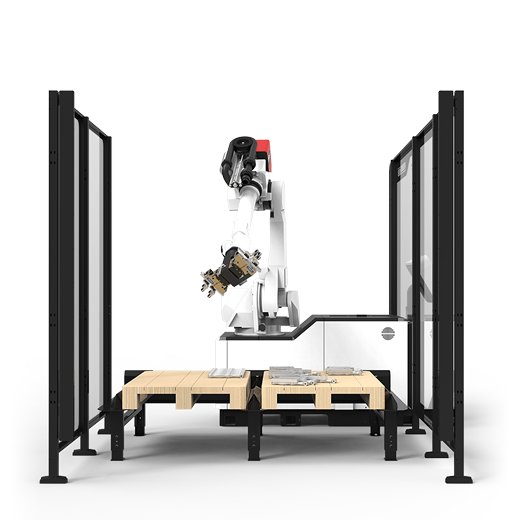

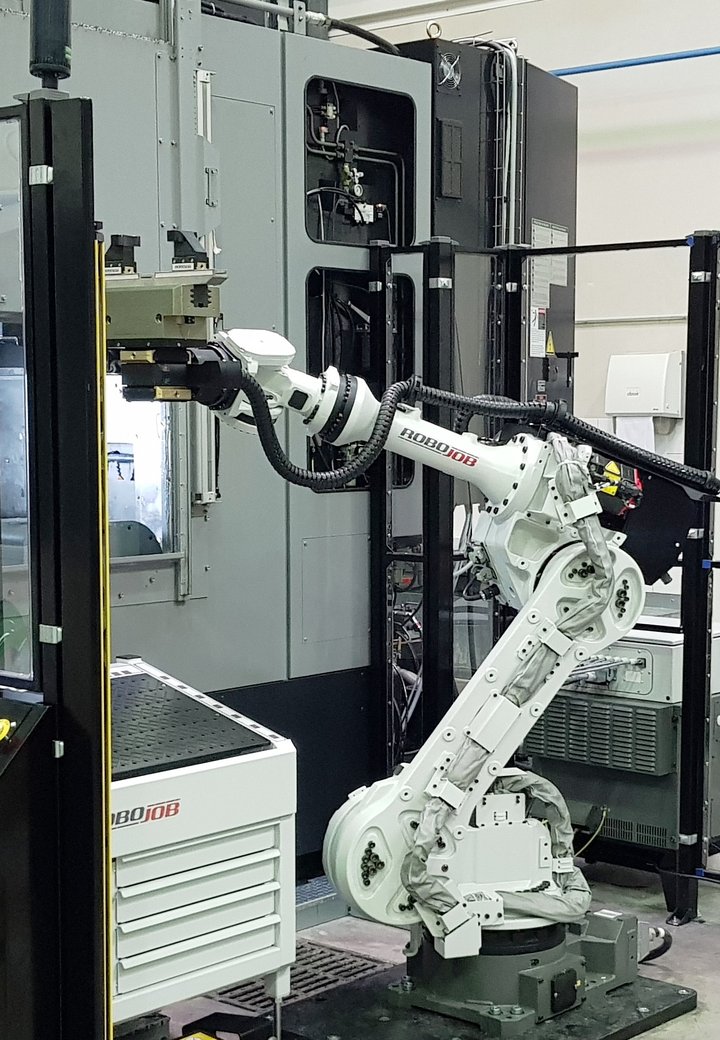

Tending CNC machines, that's what we do. Our robot solutions load rough components into CNC machines and unload the finished pieces once the batch is done. Does your production process require a helping hand during the batch cycle as well? Our robots open the door and lend a helping hand.

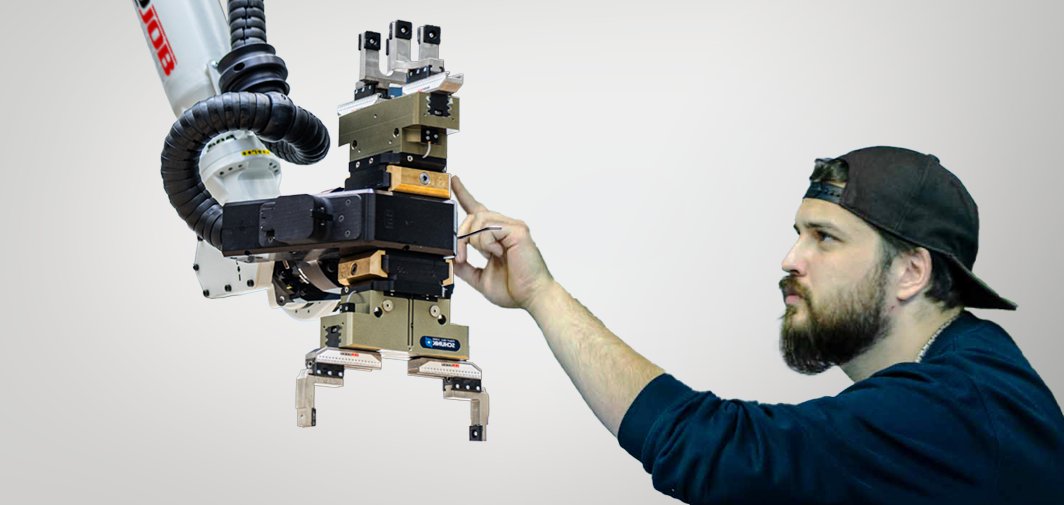

Operating our robots is intuitive, making it quick and easy. We make it our mission to get any CNC operator started with our software within a couple of minutes. Setting up a new batch in our software is child's play, enabling fast changeovers and more spindle hours.

Our RoboJob systems are highly accessible, thanks to their intuitive and user-friendly software interface. Operators of all experience levels can quickly manage and operate the robot with minimal training. The clear instructions on the screen makes automation easier and accessible as ever.

One of the key characteristics from our robots is that they are CNC brand agnostic. Our robots work with any CNC brand. In a world full of exclusiveness, we offer universatility. That allows you to use the robot for various CNC machines.

At RoboJob we automate the production process for multiple type of workpieces, varying in shape, size, and materials, whether they are complex or simple. We do so with customizable grippers and our intelligent software.

Both new and existing machines can be automated. RoboJob will assist you in the process of equipping your machine with an automatic door, the right fixtures and a robot interface.

Earned Back in...

Request a free ROI calculation

Let's mark the day on your calendar

when you start making money from your investment.

Our robots, your solution

First in CNC Automation

Our mission is to automate every CNC machine out there, whether it's a milling machine, a turning lathe or a combination of the two. In the past 18 years we have developed six mature product series including the Turn-Assist and the Mill-Assist, but you may also know our Tower, Wall, Coby CNC or Pallet-Load. We automated over 100 CNC brands, so you're definitely not the first to get started with RoboJob.

+2.000 Installations

That's +2.000 promises we've kept.

Discover the RoboJob effect in our success stories.

+2.000 Installations

That's +2.000 promises we've kept.

Discover the RoboJob effect in our success stories.

Meet our brilliant team

Behind every RoboJob product, innovation and installation is a team of passionate and talented individuals, committed to creating smarter automation solutions. Together, we turn challenges into opportunities. Together, we bring our robots to life.