Automate your CNC milling machine

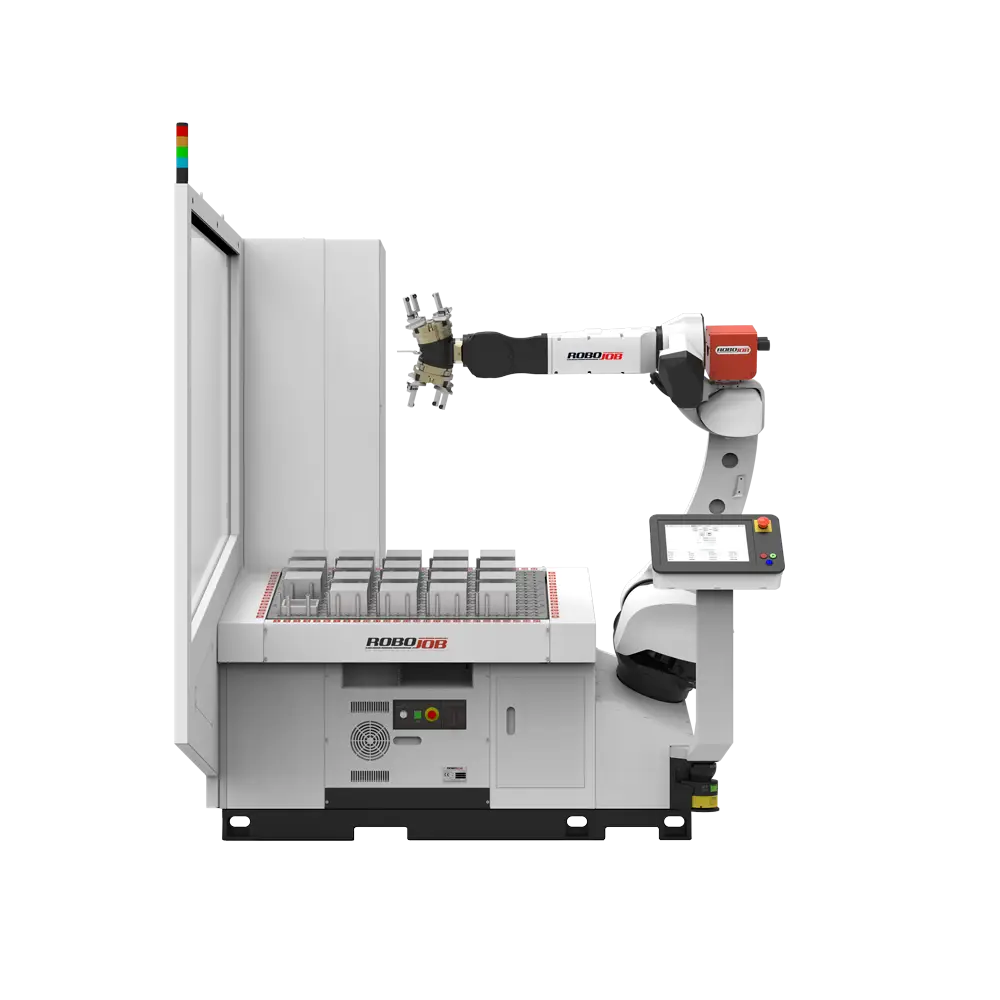

Mill-Assist Essential

Your essential standard automation for milling machines

Small runs

Fixed table with limited stacking height

Robot payload: 12kg up to 70kg

Discover

Ready for cnc automation?

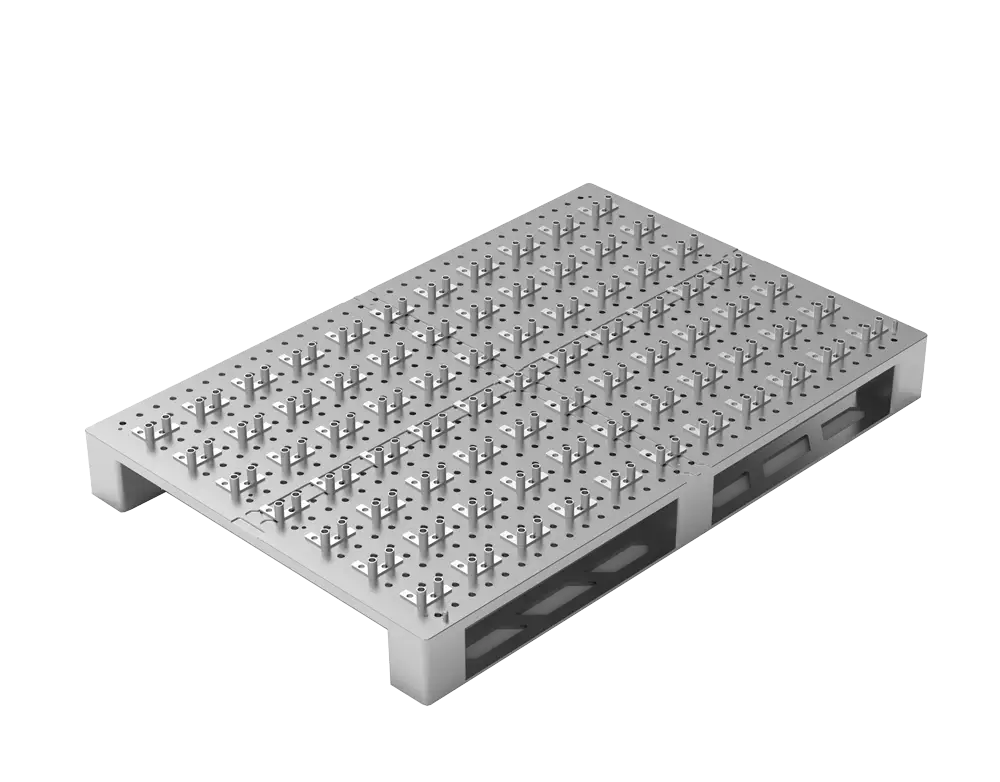

Using the Mill-Assist Essential you can set to work immediately. This easy-to-use automation has been specifically developed for the loading and unloading of small runs and/or small workpieces. You have a fixed table that you can configure yourself with workpiece supports or grid plates that you can also make yourself.

Mill-Assist Essential

Accessible and easy to use

As a result of our user-friendly interface you can automate your small runs in just a few minutes: the intuitive, graphic software guides you step by step when setting up your assignment.

Integrated

Separated

Semi-Integrated

Yes, but not in combination with Pallet-Unload

Yes, but not in combination with Pallet-Load

Automation can be complex, but it doesn't have to be.

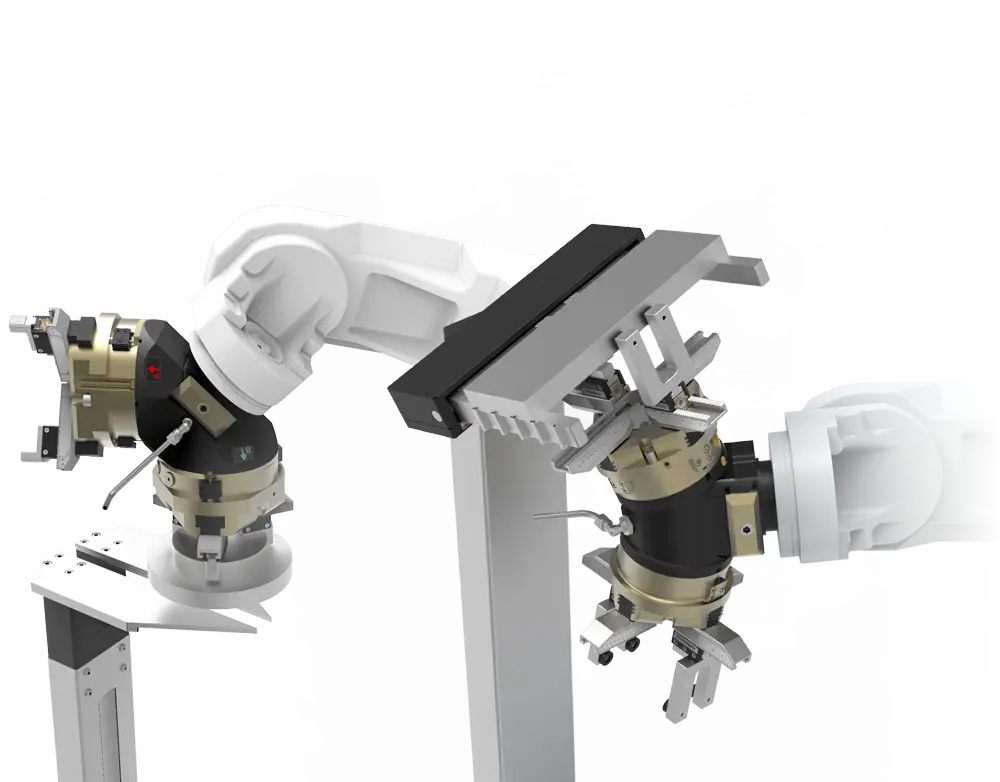

Available in three models

Integrated, Separated and Semi-integrated

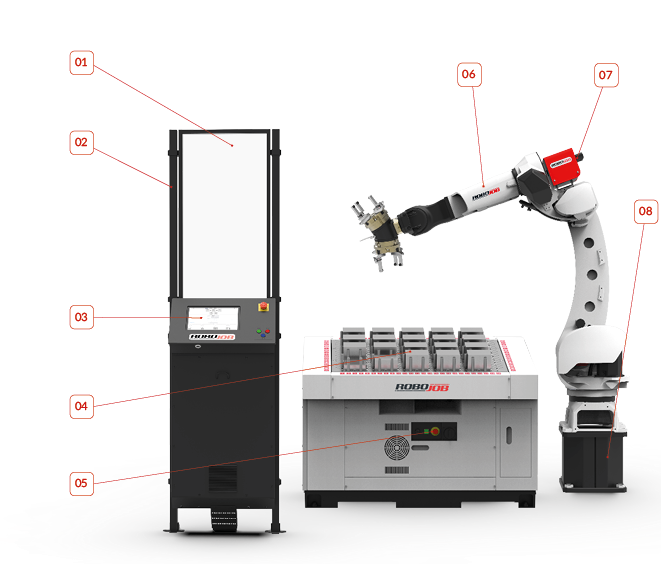

01

Safety wall

02

Light curtain

03

Control panel

04

Configurable feed and removal

05

Built-in robot controller

06

Fanuc Robot with 25 kg payload

07

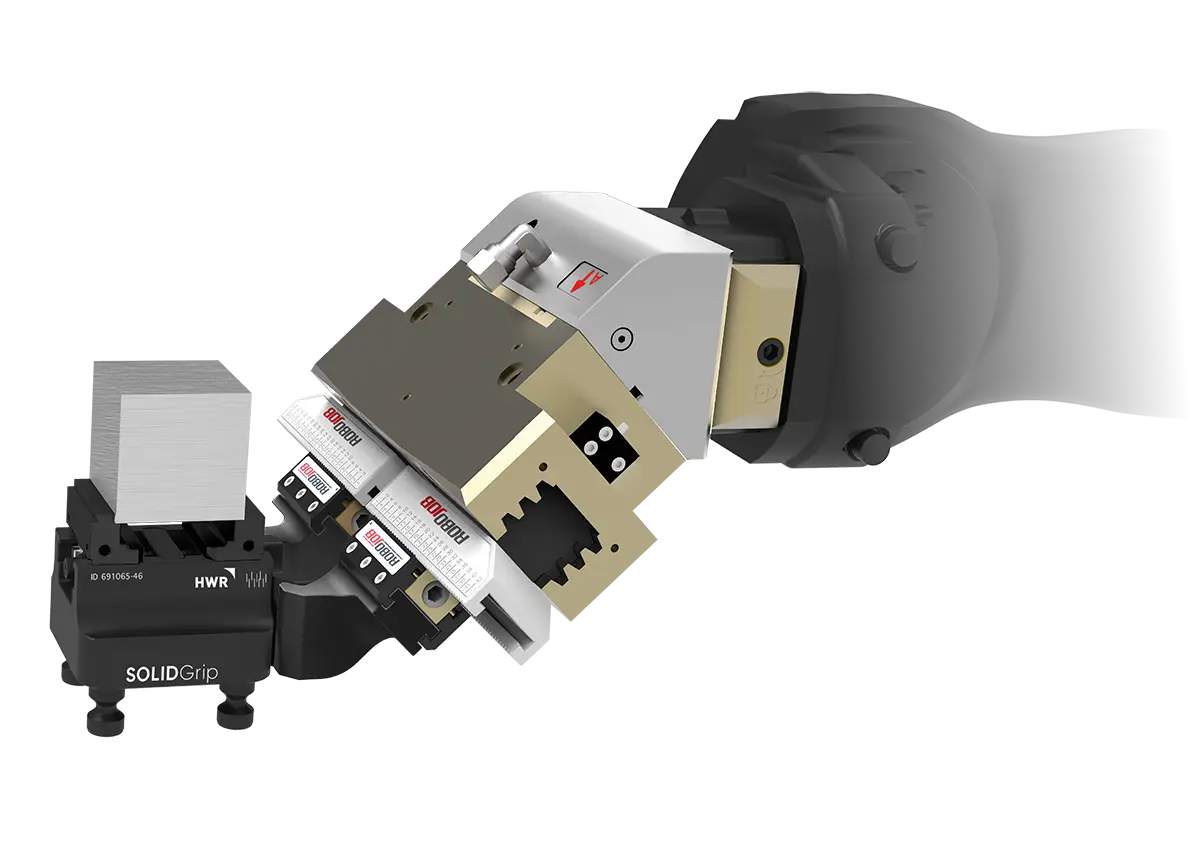

Clamping force control for grippers

08

Robot Support

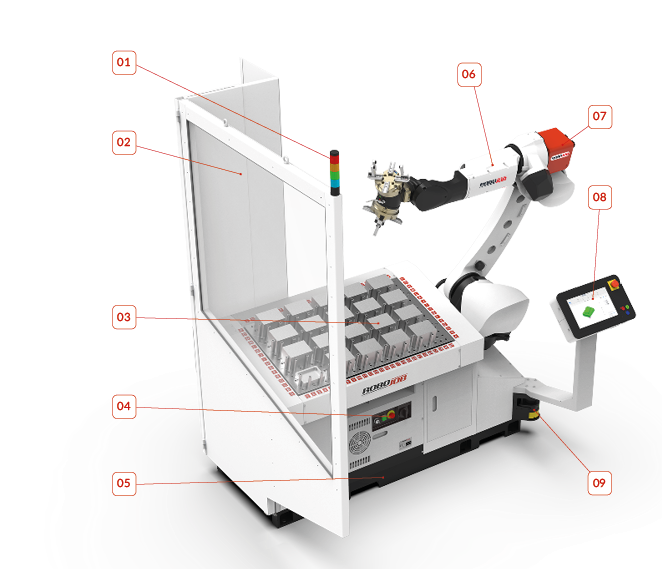

01

3 coloured signal tower

02

Integrated safety wall

03

Configurable feed and removal

04

Built-in robot controller

05

Fixed chassis & anchoring points

06

Fanuc Robot with 25 kg payload

07

Clamping force control for grippers

08

Control panel

09

Laser scanner

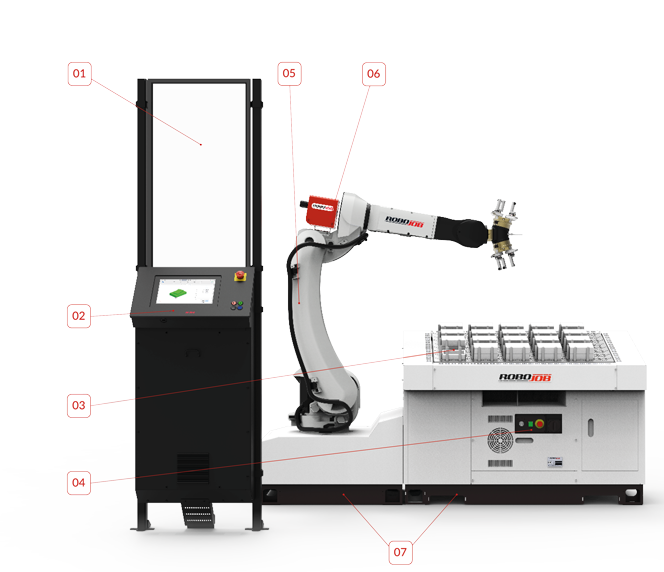

01

Safety wall

02

Control panel

03

Configurable feed and removal

04

Built-in robot controller

05

Fanuc Robot with 25 kg payload

06

Clamping force control for grippers

07

Fixed chassis & anchoring points

Mill-Assist Essential

Integrated

The entire automation system is built on a single chassis, which makes this model quick to install and also easy to move. This model can be placed at the front or side of your milling machine, while the door remains constantly accessible.

Separated

The table, robot, industrial PC and safety wall are physically separated from each other. This offers more flexibility in terms of set-up and robot type, which allows us to go up to 70kg payload capacity.

Or would you rather talk to someone?

Contact us directlyFurther complete your RoboJob system

Modular extensions for your Mill-Assist Essential