Mill-Assist

The Mill-Assist takes CNC automation to the next level - compact, smart, and so easy to use it practically runs itself (but you still get all the credit).

Mill-Assist: Precision automation for CNC milling

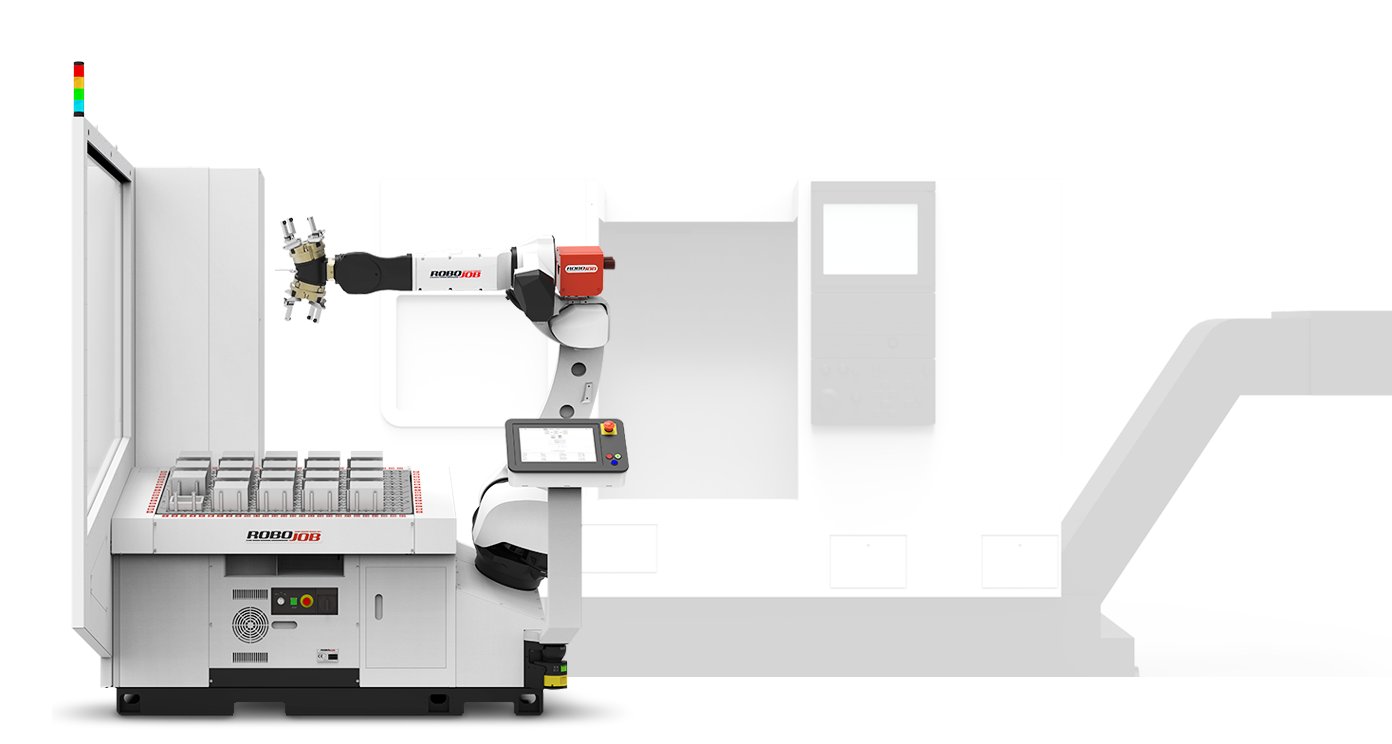

Since its launch in 2012, the Mill-Assist has brought smart automation to CNC milling, offering compactness, versatility, and ease of use. Designed for a variety of workpieces, it maximizes capacity in a limited space while enhancing flexibility and efficiency.

Now in its second generation, the Mill-Assist incorporates years of customer feedback and technological advancements to deliver unmatched performance and adaptability. With its intuitive interface, intelligent grippers, and robust features, it simplifies automation for operators of all levels.

For over a decade, the Mill-Assist has transformed milling operations worldwide, providing reliability and efficiency for small-series production and demanding workflows alike. It remains the trusted choice for workshops looking to elevate their CNC milling to the next level.

A model and configuration for every shop

The Mill-Assist adapts to every workshop with flexible solutions tailored to your needs.

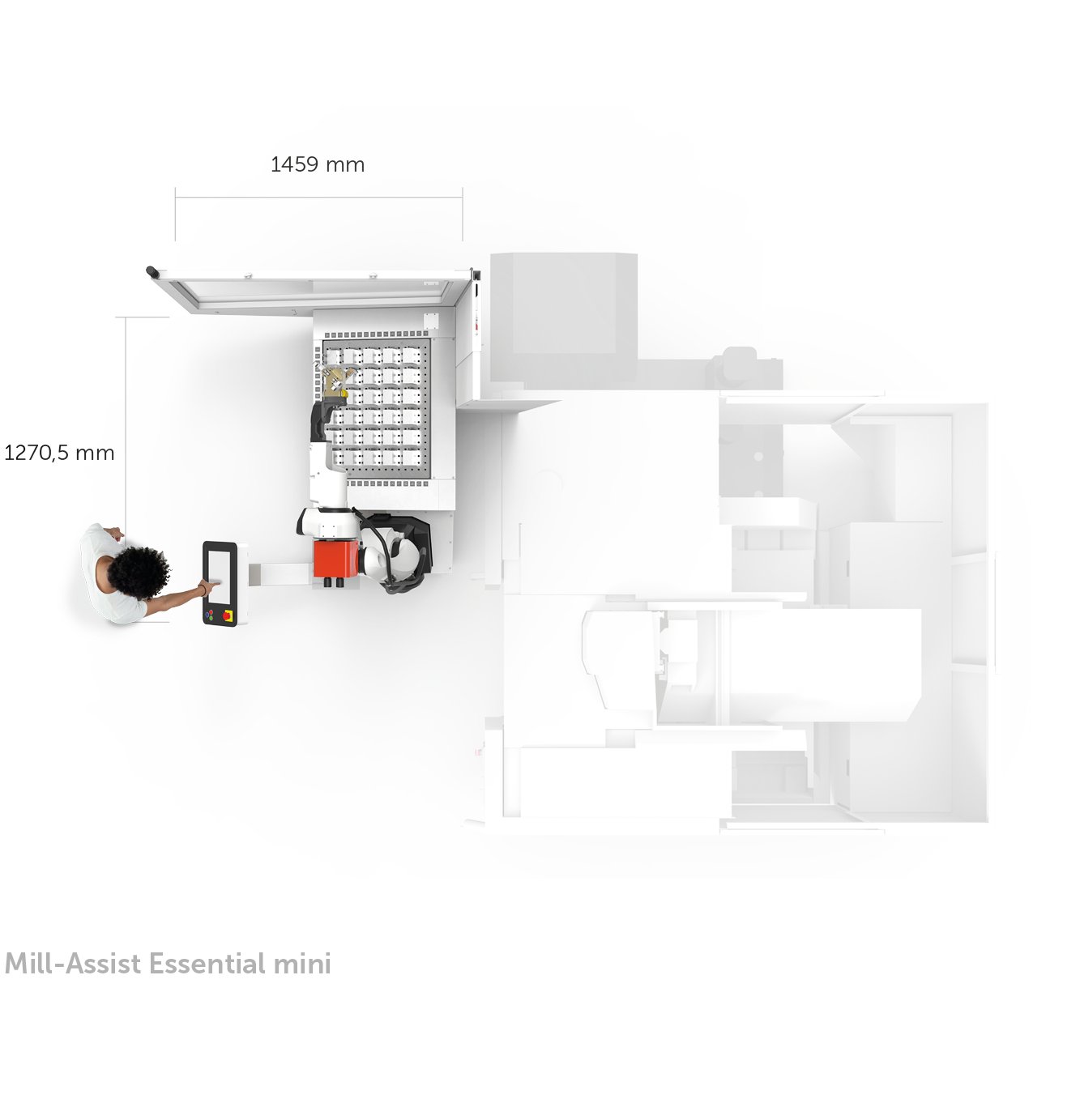

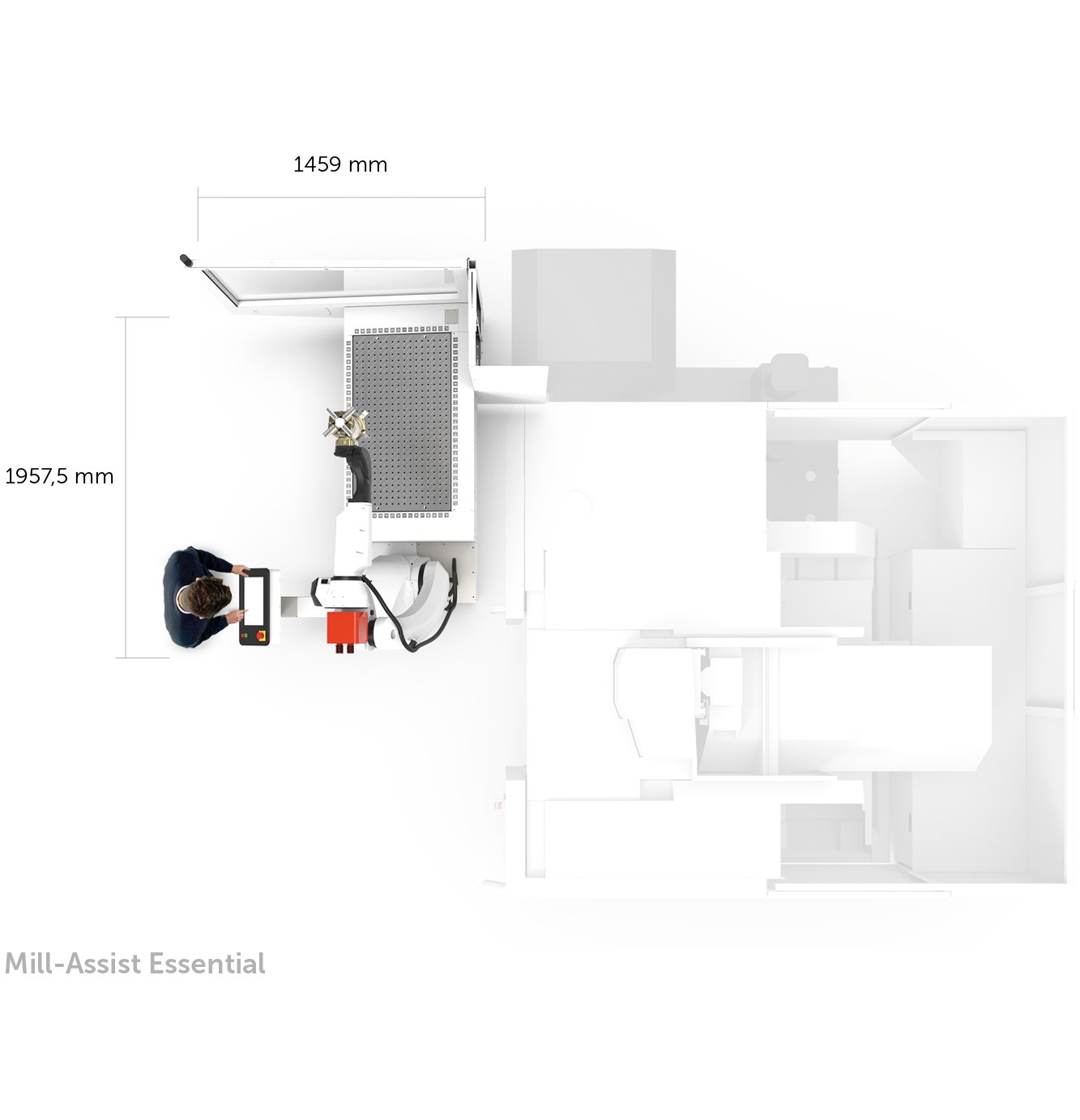

Choose the compact Essential Mini, ideal for smaller spaces, or the larger Essential table, available in three configurations:

- Integrated: A compact, all-in-one design for quick installation.

- Semi-Integrated: Combines flexibility and space efficiency, ideal for side-door loading.

- Separated: Offers maximum adaptability with independently placed components, suited for unique layouts or tool magazine access.

Automation without hassle

Accessible Automation for Every Workspace

At RoboJob, we simplify CNC automation. The Mill-Assist integrates effortlessly into any factory layout without requiring major adjustments. It seamlessly complements your workflow, ensuring minimal disruption.

Compact Design, Maximum Efficiency

With its small footprint, the Mill-Assist is perfect for crowded or compact production areas. Its open design provides full access to your machine - no cages or barriers needed. This makes automation more efficient and space-saving than ever.

Works with Any CNC Machine

The Mill-Assist is compatible with all CNC brands and models. Its flexible setup adapts smoothly to different layouts, machines, and workflows. RoboJob is committed to making automation easy and accessible for manufacturers everywhere.

Flexibility to match your needs

The Mill-Assist is as versatile as your production demands. With just one system, you can handle a wide range of workpieces - no matter their shape, material, or weight. From small, delicate parts to heavier, more robust components, the Mill-Assist adapts effortlessly to keep your production running smoothly.

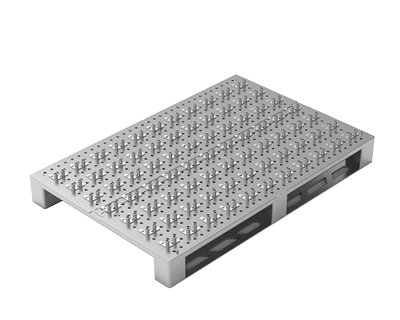

The Mill-Assist’s configurable table enables the automation of a wide variety of workpieces without the need for extra equipment like grid plates, though optional. Powered by RoboJob’s patented technology, its innovative design ensures seamless job switches, maximizing uptime and efficiency. Simplify operations and stay competitive with flexible, hassle-free CNC automation.

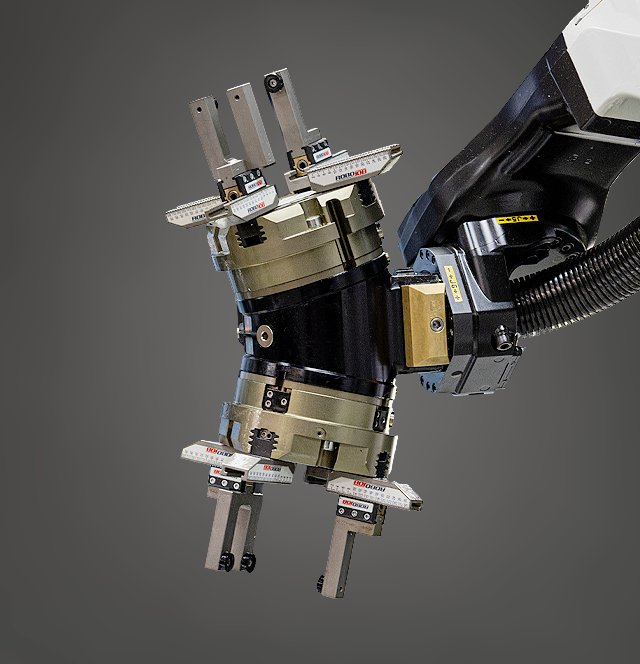

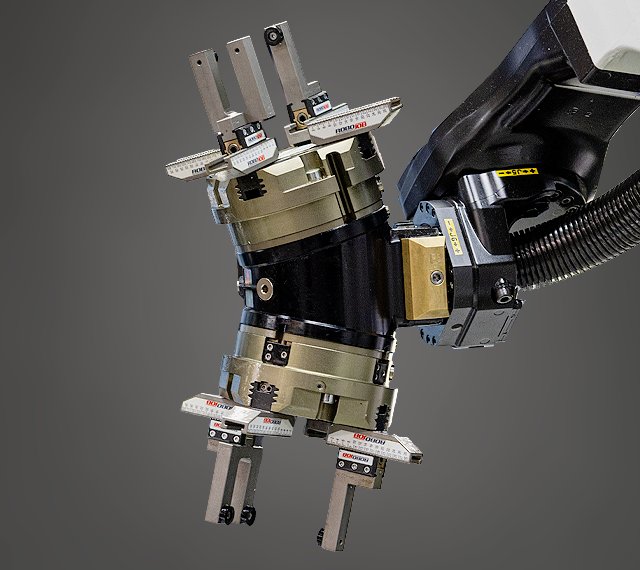

The Mill-Assist comes equipped with two highly versatile grippers, designed to handle virtually any workpiece. Whether you're dealing with different sizes, shapes, or materials, you can instantly adapt or exchange the grippers. Switching between products has never been this fast and easy.

Flexible automation for any CNC mill

The Mill-Assist has been the industry’s standard for CNC milling automation for over 15 years, offering unparalleled flexibility for handling a wide variety of workpieces. Unlike imitators, the original Mill-Assist stands out thanks to its speed, adaptability, and modular design - all tailored to meet your production needs. It's the trusted choice for those who demand efficiency, versatility, and precision in automation.

User-friendly by design

From setup to operation, everything is quick, easy, and operator-friendly - saving you time and effort every step of the way.

The most user-friendly software on the market

The Mill-Assist features intuitive software that’s designed with the operator in mind. With 3D visualizations of your workpiece, grippers, table and fixtures, you can set up a new job in just 5 minutes. Save your configurations, recall them instantly, and keep production flowing effortlessly - job after job. The multi-touch interface ensures smooth and effortless operation every time.

Easy setup, instant productivity

When your Mill-Assist is installed (in less than a week), it’s ready to work right out of the box. Grippers and tables are easy to configure, thanks to the system’s clever design and included accessories. Start automating immediately - there’s no steep learning curve.

Smart and safe features for a simplified workflow

The Mill-Assist combines smart functions like Start & Stop, Home mode, and adjustable gripper force to save time, boost precision, and simplify tasks. Integrated safety features, including advanced sensors and intuitive safeguards, ensure a productive and secure working environment, protecting operators while maximizing efficiency.

Personalize your Mill-Assist with smart Modules

Find your ideal automation solution.

Discover how CNC automation can enhance precision and safety in your manufacturing process. Use our wizard to find the best fit.

Let's get in touch

Learn more about automating your CNC mill today.

Get in touch with one of our representatives.