72 hours of autonomous machining

Tower

A revolutionary total solution for the loading and unloading of your CNC turning lathe, milling machine or turning/milling combination

Single pieces to large runs

Exchange of clamping devices

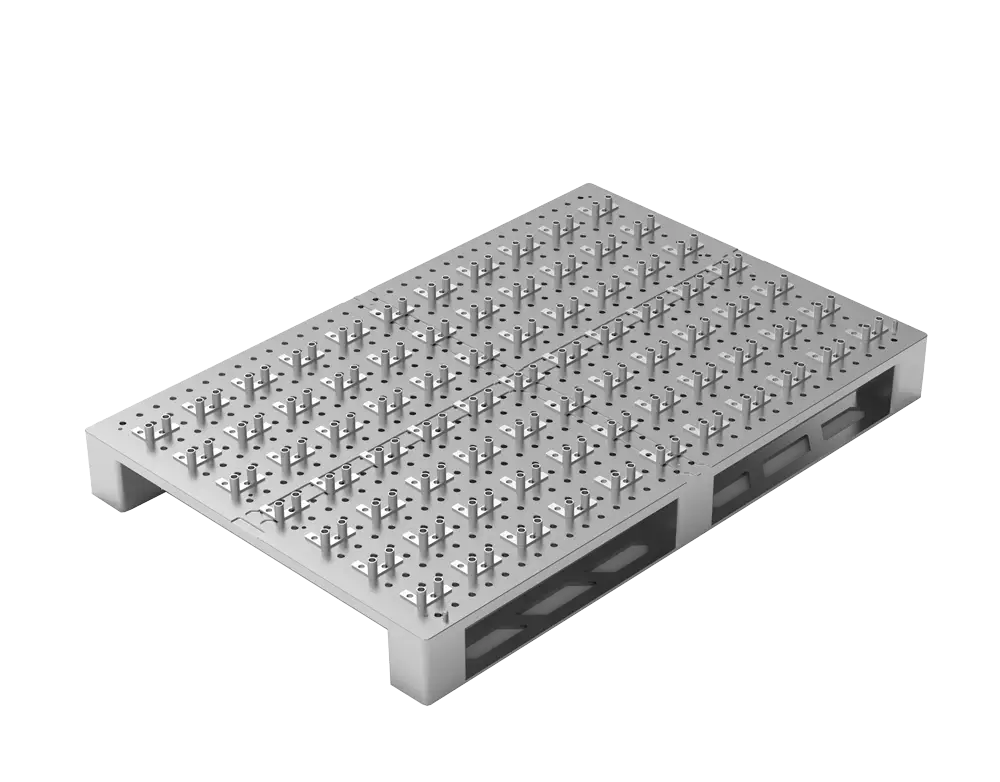

Workpiece or pallet loading

Discover

A revolutionary total solution

The new Tower was specifically developed to produce for 72 hours, unmanned and autonomously. Not just serial work, but also single pieces. Everything together: High mix, Low volume. This way, you can prepare the Tower on Friday morning and continue production through to Monday morning. Because it’s only in this way that you can get the most out of the CNC machine.

RoboJob Tower

Smart

A servo gripper? Check. One robot serving 2 machines? Absolutely. Even a turning lathe and a milling machine if possible. You can do it all with the same user-friendly software that you are used to from RoboJob. Including Job Scheduler, pallet gripper and much more.

3.5m high

4.6m high

Yes, but not in combination with Pallet-Unload

Yes, but not in combination with Pallet-Load

The Tower is the all-rounder in RoboJob’s wide range.

Models

3.5 m and 4.6 m

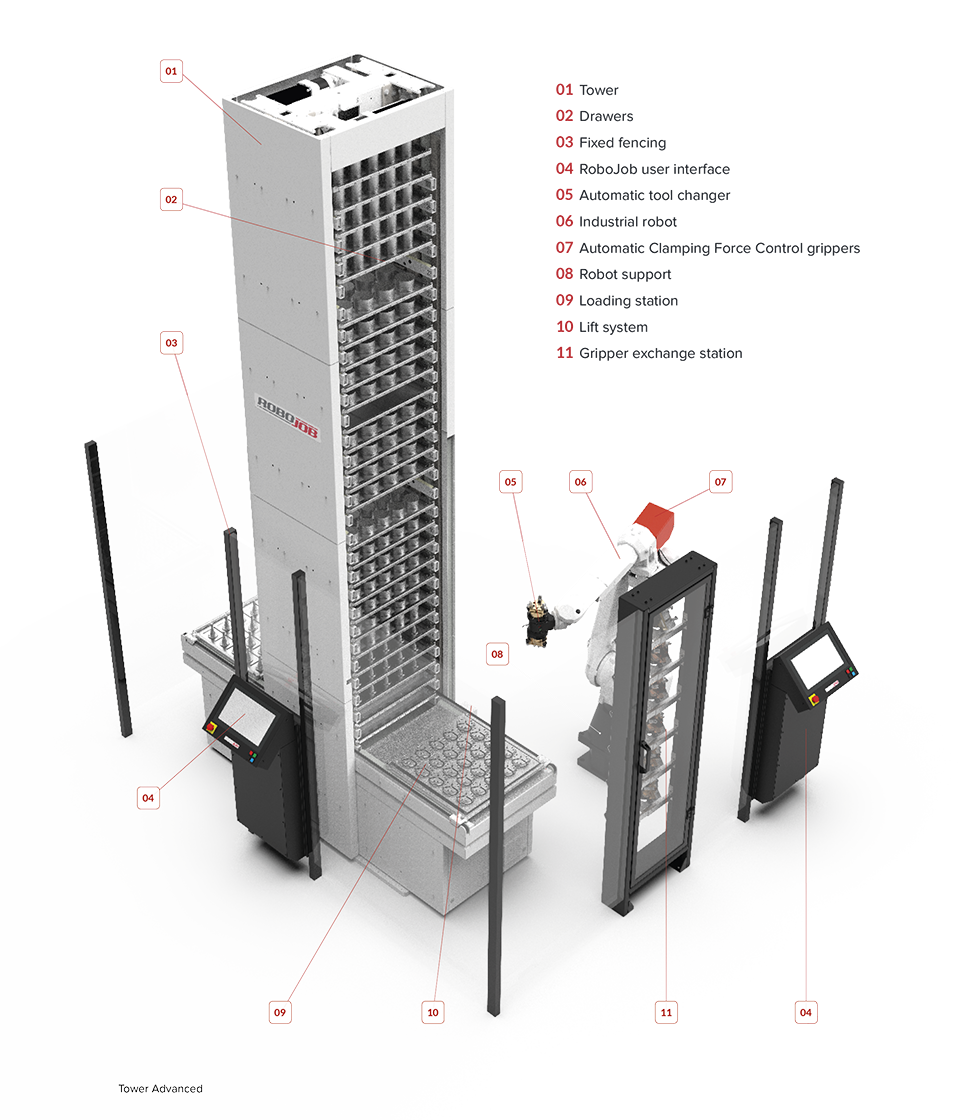

01

Tower

02

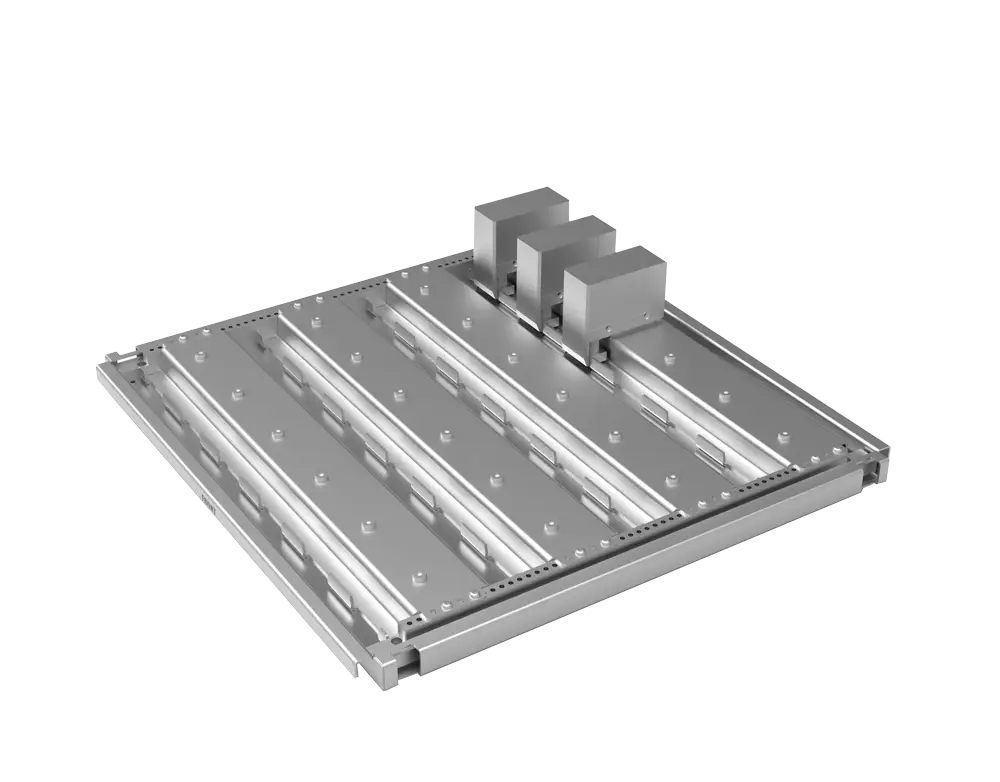

Drawers

03

Fixed fencing

04

RoboJob user interface

05

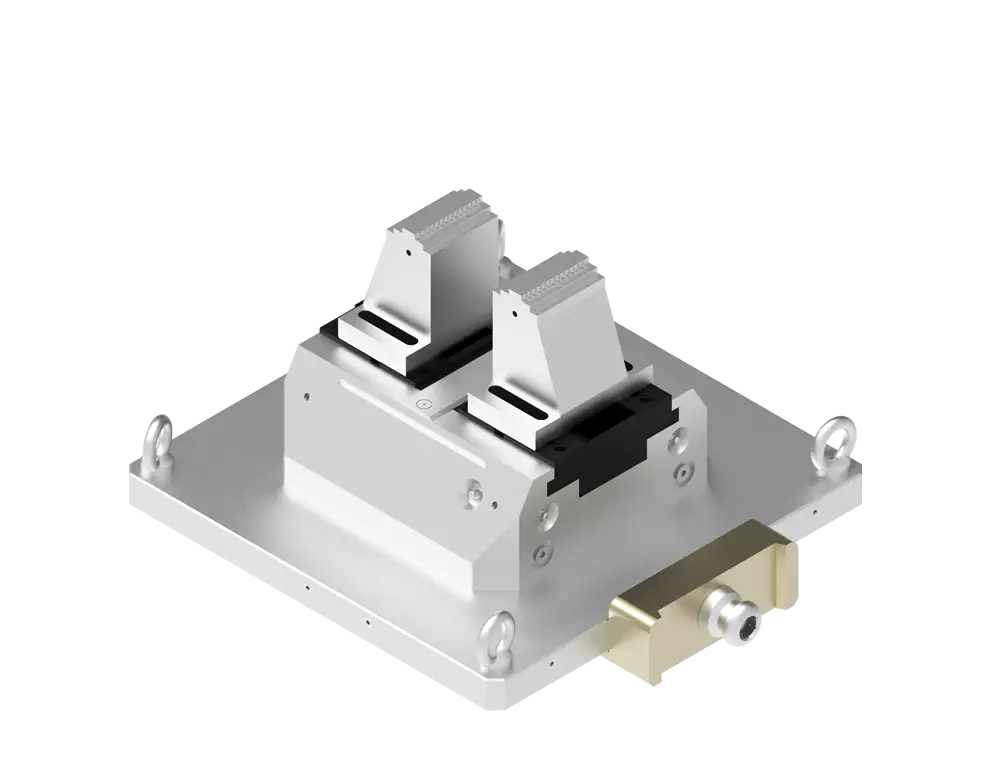

Automatic tool changer

06

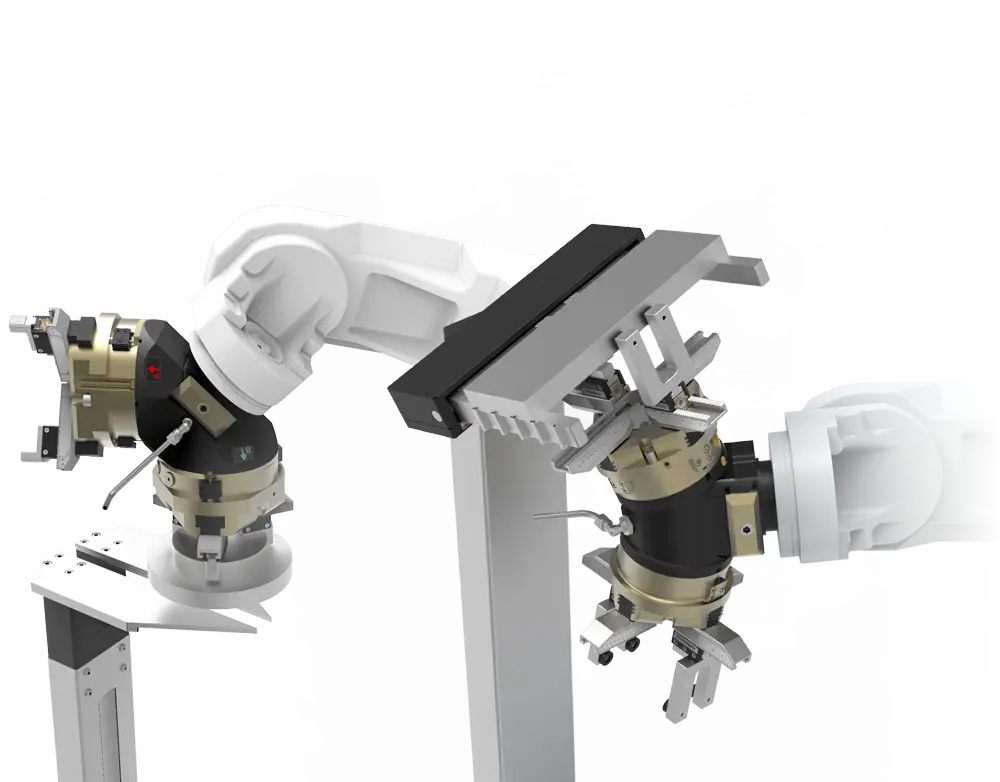

Industrial robot

07

Automatic Clamping Force Control grippers

08

Robot Support

09

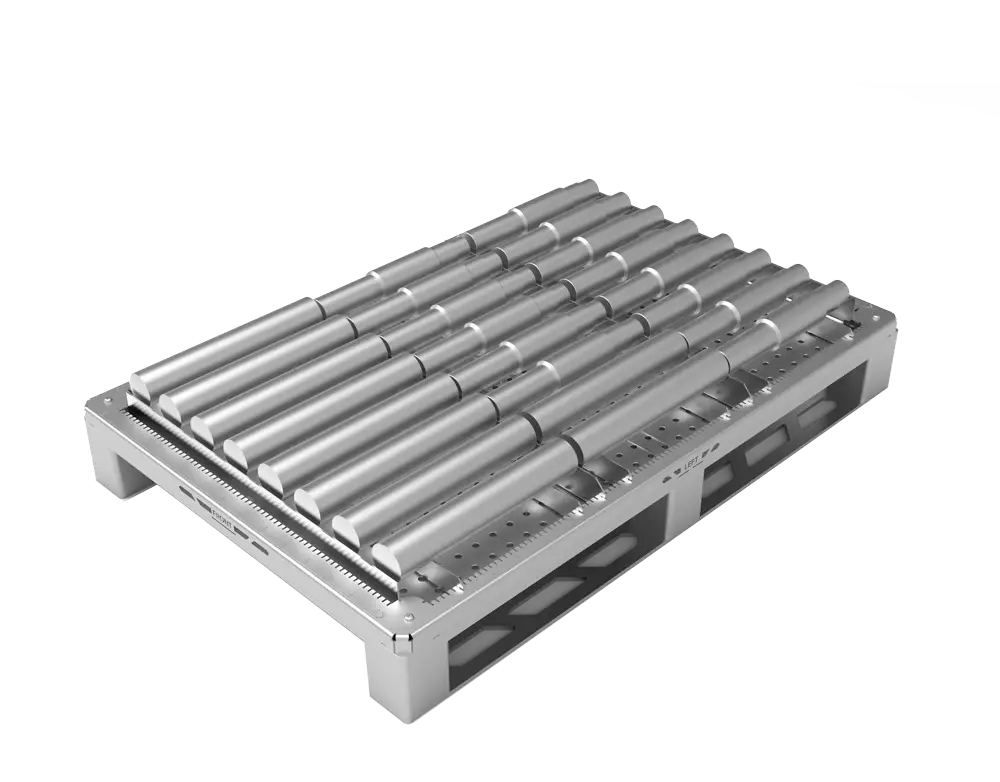

Loading station

10

Lift system

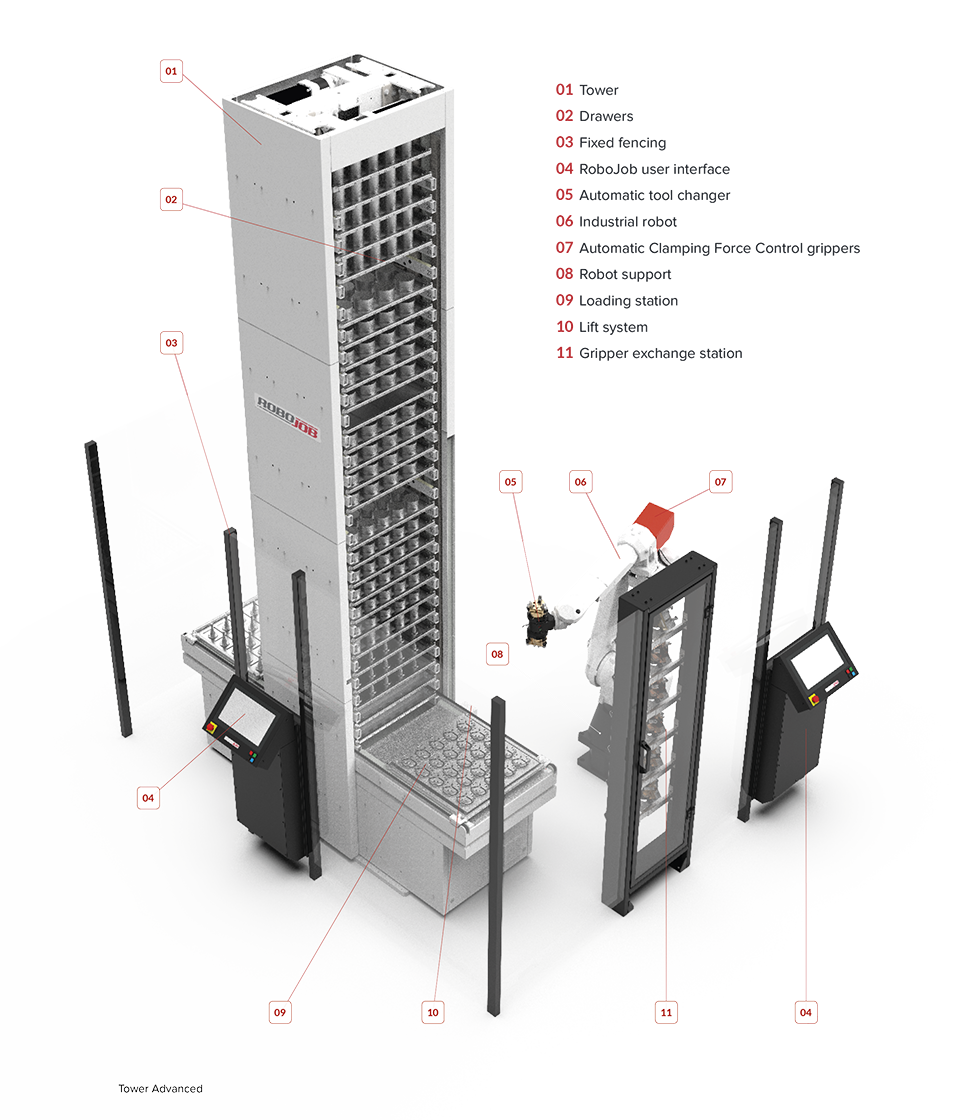

01

Tower

02

Drawers

03

Fixed fencing

04

RoboJob user interface

05

Automatic tool changer

06

Industrial robot

07

Automatic Clamping Force Control grippers

08

Robot Support

09

Loading station

10

Lift system

Features

Extremely easy to use

The “brains” of the Tower are, of course, in the Software and the accompanying User Interface. These enable you to put your Tower to work as quickly and easily as possible. At the same time, we want to offer you as many functionalities and possibilities as possible. You’ll find that it’s our Software that makes the difference.

Flexible set-up

As you would expect from RoboJob, we offer you a great deal of flexibility. Not only in functionality, but also in the wide range of configurations on which you can assemble your Tower.

Want to speak to someone now?

Get in touch with us today.FURTHER COMPLETE YOUR ROBOJOB SYSTEM

Modular extensions for your Tower system