Even before the 'lockdown light' came into force in Belgium, most of the more than 60 RoboJob employees had already started working from home. The tools and systems needed to keep everyone working smoothly, efficiently and safely were quickly put in place, which allowed the RoboJob team over the past few months to continue working on the future. "Once we were able to assess the seriousness of the situation, we stopped production for a few weeks," says Helmut De Roovere, CEO. "Fortunately, we were able to continue to support our customers remotely, and we were even able to go on site when it was really necessary. It goes without saying that we did not sit idly by. If there is one thing that this crisis has made clear in our industry, it is that we must once again produce locally in Western Europe, instead of outsourcing orders to cheaper producers in the Far East. Of course, that is easy to say. If you do the calculations, you realise that this is only possible through the use of automation. And this is where we come in."

"We expect a substantial peak in orders this year, and we have already noticed an increase. It was heart-warming to receive positive messages from our customers from all over Europe during our 'lockdown light' in Belgium. They let us know that thanks to our robots they could continue to produce, and some of them even sent us video clips. Of course, all these messages came from companies that were quick to focus on automation in recent years. They are now reaping the benefits," declares De Roovere.

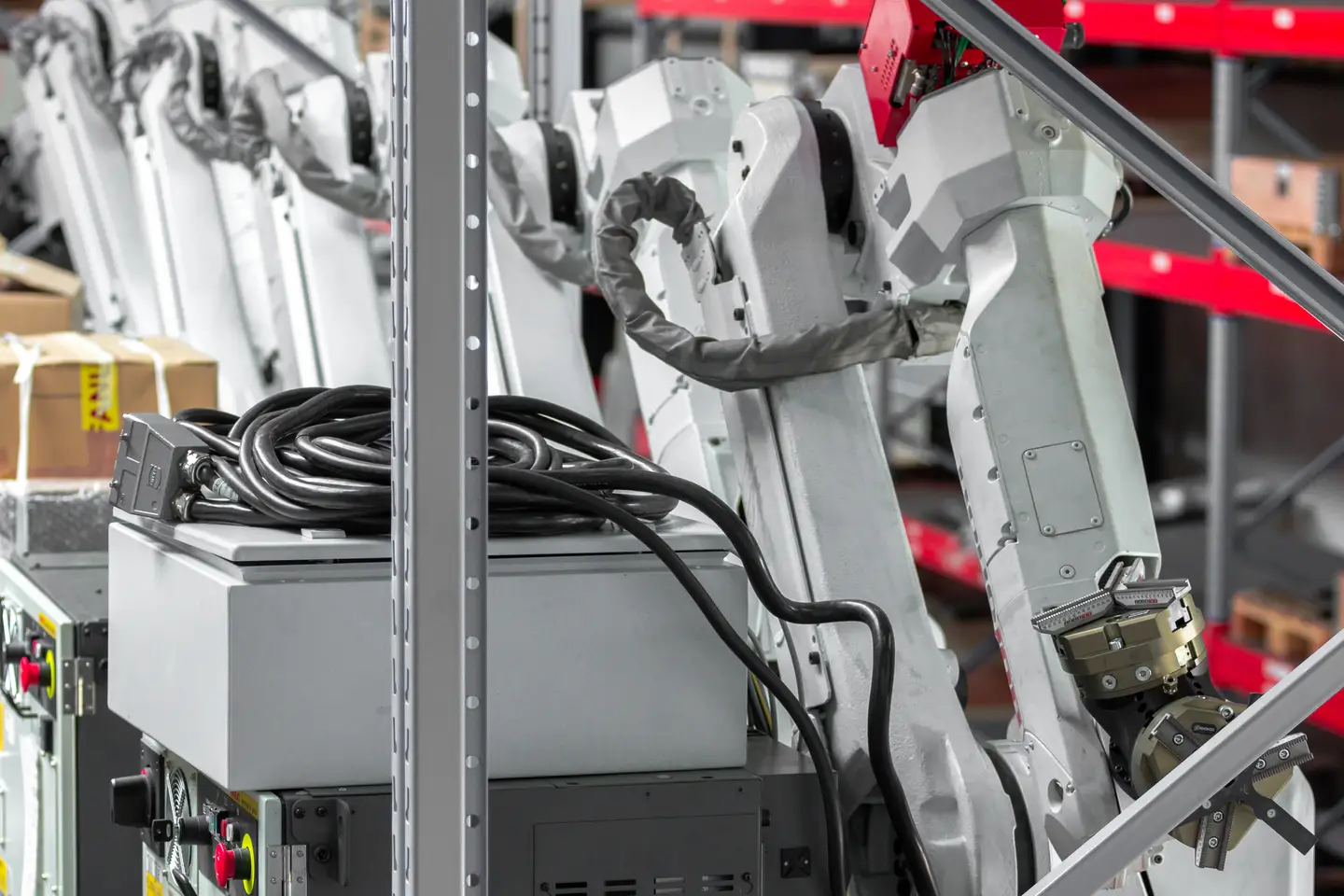

The majority of manufacturing companies, however, have not yet taken the step towards CNC automation, and RoboJob is well aware of that. “Spindle hours are becoming more important than ever. Every CNC machine must generate profit, even if a virus dictates that there are few or no operators available. It is no longer a question of if you need to automate, but rather how you are going to do it. At RoboJob, we can offer our customers the most extensive portfolio in CNC automation, and we already have more than 800 installations under our belt at home and abroad. Nobody else in our sector comes close to that."

And so it is all hands on deck at RoboJob. Production was restarted as early as the beginning of April, and in recent months we have continued to work hard on product innovations and new functionalities. The installation technicians are also back at work, just like all the other teams. There are no more trade fairs scheduled for this year, but this will free up a lot of time to plan all the installations. "And that will be necessary," De Roovere says knowingly. "But we are ready for that. Our customers should by now have realised that it is imperative to invest in the automation of their machine park. Now more than ever.