Automation is on the rise. When the first regions and countries went into lockdown at the end of March, thousands of companies were forced to close their doors. Employees had to work from home, and various production companies came to a complete standstill. With the exception of those companies that had focused on automation in recent years.

“We received spontaneous messages from our customers all over Europe,” says CEO Helmut De Roovere. Our customers told us that thanks to their RoboJob system they managed to keep producing. We are extremely proud that we were able to assist them in this.”

"We also find that we’ve received a lot more requests since the summer. The number of orders is also on the rise. Companies all over Europe are now realising just how important it is to invest in CNC Automation,” says De Roovere. "Many of them don’t have any experience with robots yet." Today RoboJob already has the most extensive portfolio in CNC Automation: the Turn-Assist Series, Mill-Assist Series, Racks and Tower offer various solutions and concepts for automating turning machines, milling machines and turning/milling combinations. Both product loading and pallet loading are possible, and single pieces to larger series can be automated in a flexible and efficient way.

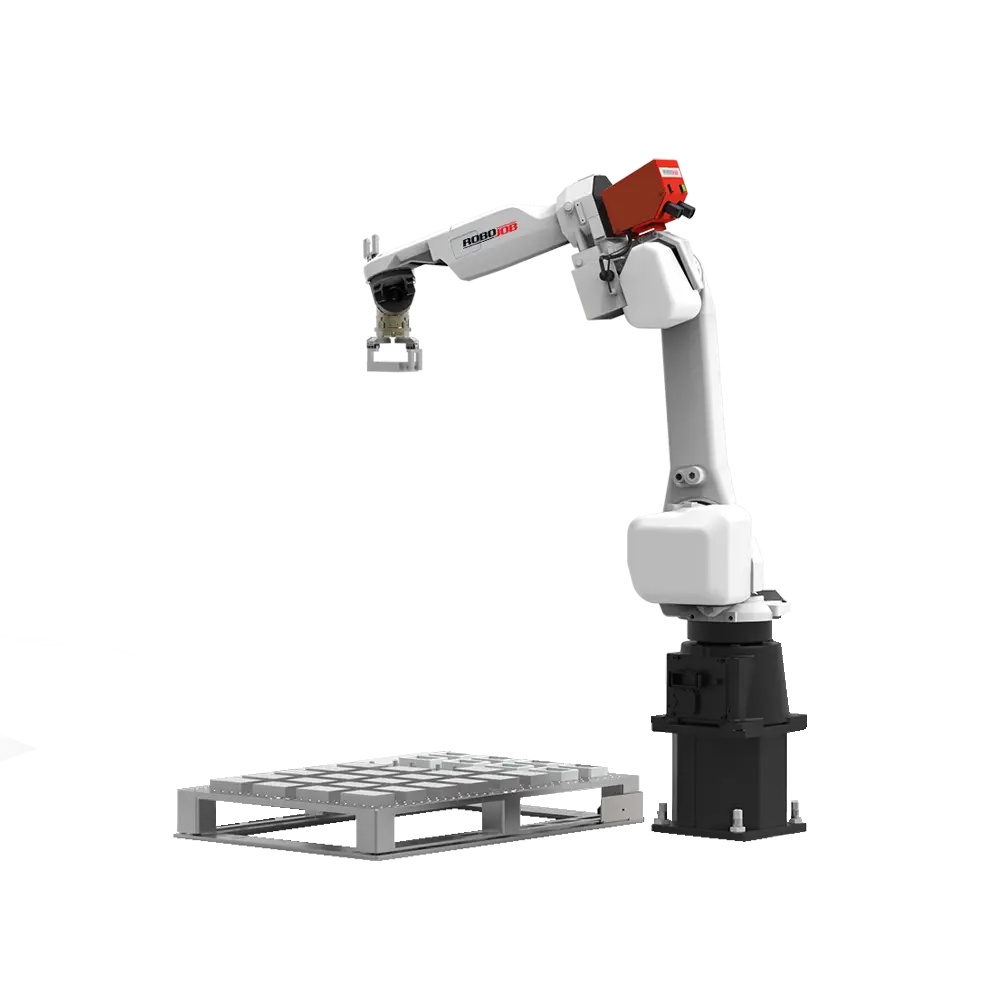

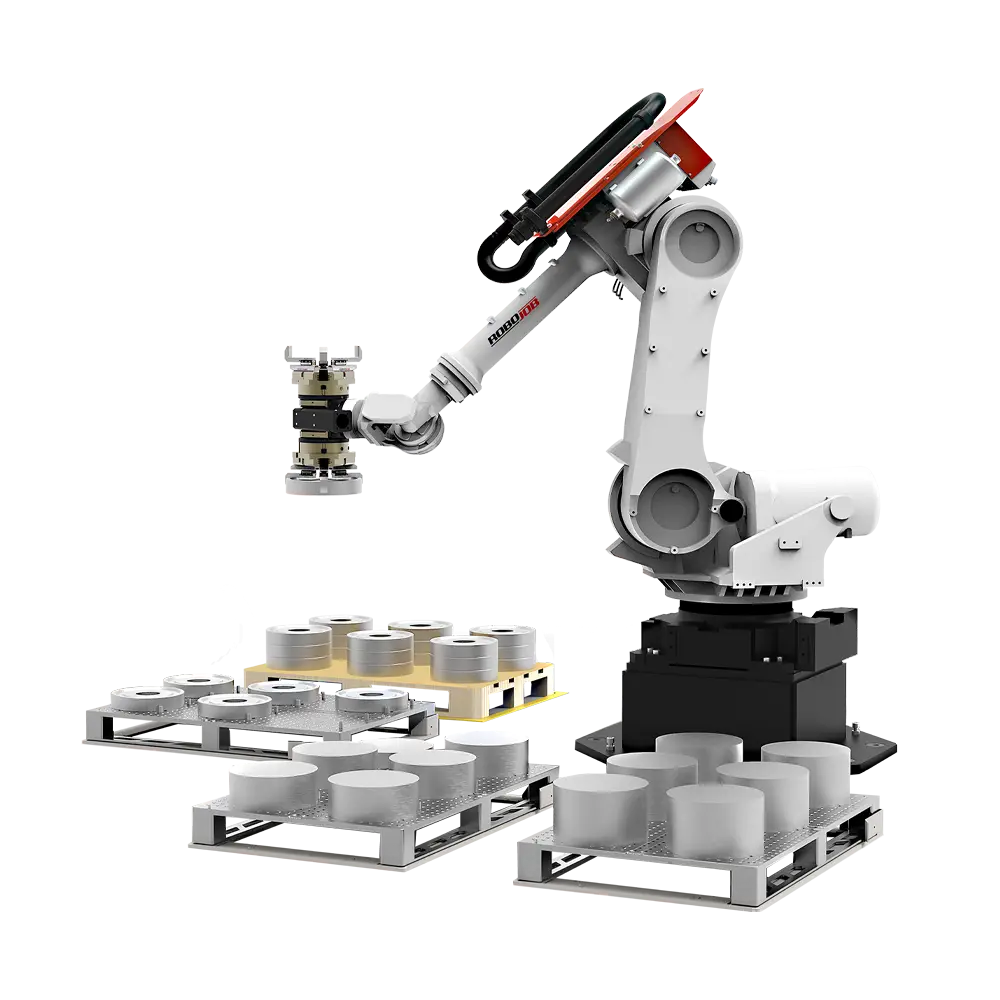

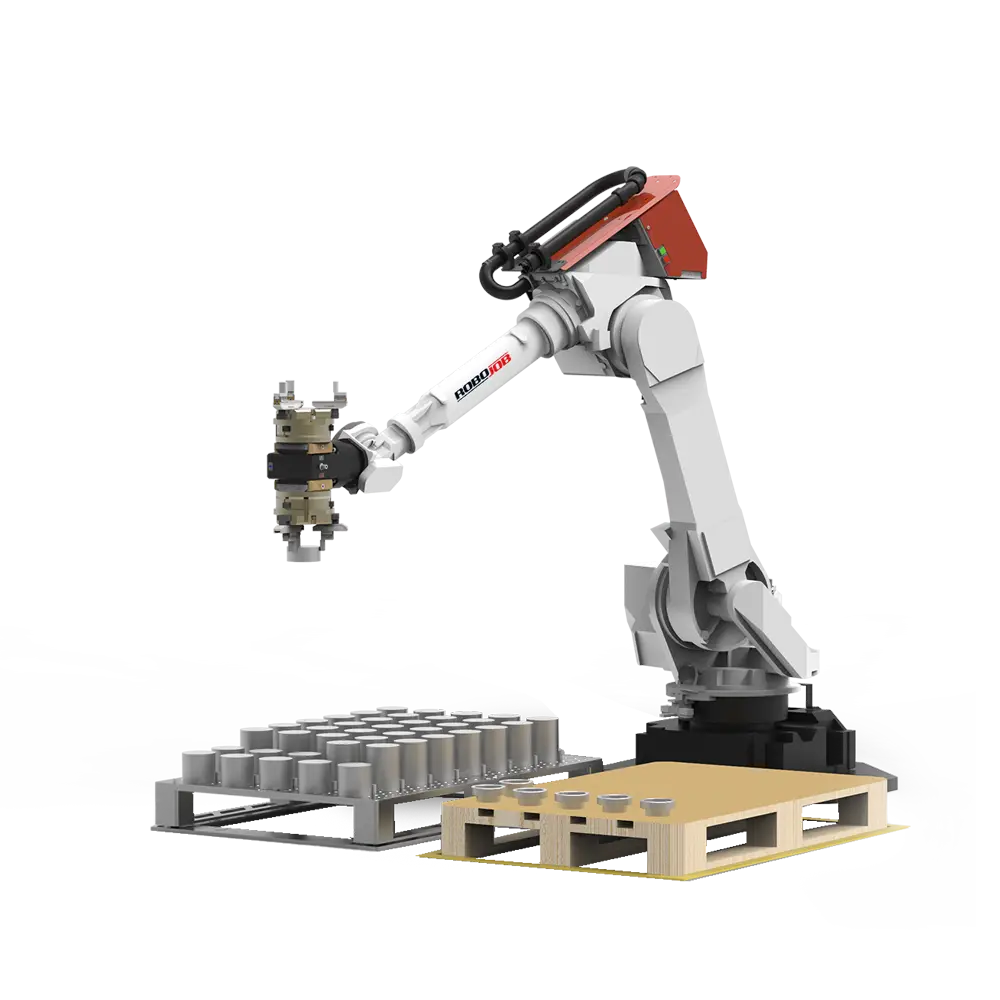

“In order to serve our customers even better, we are expanding this portfolio even further”, says De Roovere. “Together with our customers we have developed a new, accessible concept: the Pallet-Load Series. This is an extremely simple solution, consisting of a robot, one or more pallet positions on which the workpieces are positioned, a safety concept and the operation using an industrial PC. In fact, it couldn't be easier. With Pallet-Load, we are therefore focussing on those companies that have little or no experience with robots. Thanks to our user-friendly software, operation is child's play, and really anyone can get started.”

It should come as no surprise that the new Pallet-Load Series has been created in collaboration with its customers. “Many innovations and new products come into being through co-creation,” says De Roovere. “Our customers work with our solutions every day, and very often new ideas therefore come about on the work floor. In recent years, we have been able to automate more than 60 machines with a Pallet-Load solution. All teething troubles have therefore been resolved and we can now launch it as an optimised automation concept.”