“It’s quite something,” De Ceuster starts. “I can still remember when Helmut called me up in 2007 asking if we could put our heads together in order to develop a new project. I already knew Helmut from my student days and professionally we also often came up against each other. Thus we quickly got together. In the meantime that 'project' has created a new market segment and every day we are still getting a kick out it!”

“And so we should,” agrees De Roovere. “We have a young, dynamic team and it should also stay fun for them.” And fun or ‘plezant’ - as they so beautifully say in Flemish - it still is. Because this year the market leader in CNC automation in the Benelux is still hoping to finalise its two hundredth installation before the summer. Or how a project can become a beautiful story in entrepreneurship.

RoboJob owes its origins to a well-known issue: in Belgium and in many other West European countries, wages costs have sky-rocketed over the last 20 years. That has eaten substantially into the margins of the machining companies. On top of that, it’s also a fact that you can’t just pick up experienced CNC operators off the street. “In Belgium it’s a labour market problem: these are highly trained technical people, who have needed years of experience in order to master all the tricks of the trade," said De Roovere, "and unfortunately the profession is not considered very attractive, mainly by young people. We want to do something about that”. Since the start of the economic crisis, a number of problems emerged at sister company Aluro CNC, including the decline in the batch size of orders. People didn’t just want smaller order sizes, they also wanted faster delivery times and all this at capped prices. And De Roovere believes that “That won’t change any more. Stocks cost money and thus people want everything delivered just-in-time’ and in smaller quantities. Among other things they’ve also looked at the possibilities of production in low-wage countries."

A study by Aluro CNC found that the CNC operators spent enormous amounts of time on repetitive, physical work, and far too little on creative work such as programming and setting up CNC machines, the exciting part of the job. De Roovere wanted to automate those repetitive tasks, especially in small and medium sized runs. In his quest for flexible, fast set-up automation, he returned from a fruitless trip. So he decided to set to work himself: indeed he had the experience of both machining as well as mechanical engineering. By recruiting Luc De Ceuster as an expert in software programming, RoboJob was born. First as a project, but soon the interest from other machining companies quickly grew.

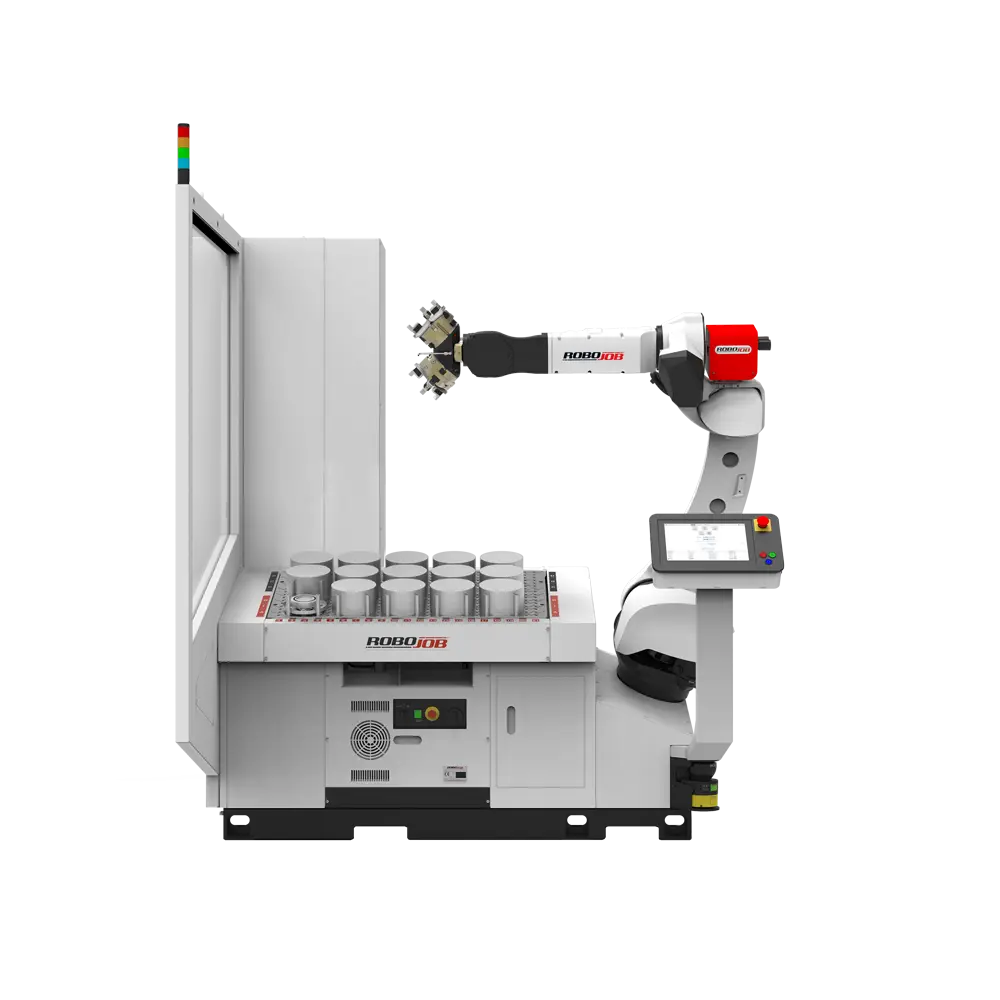

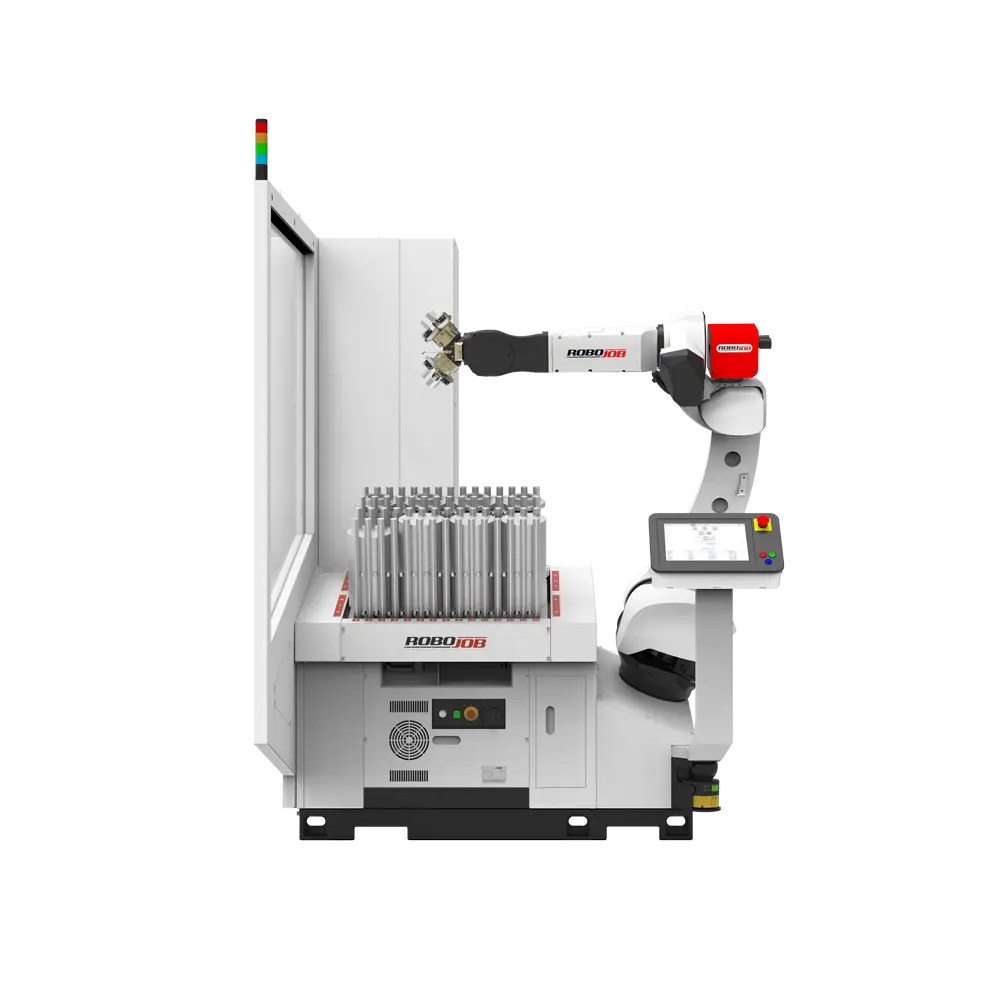

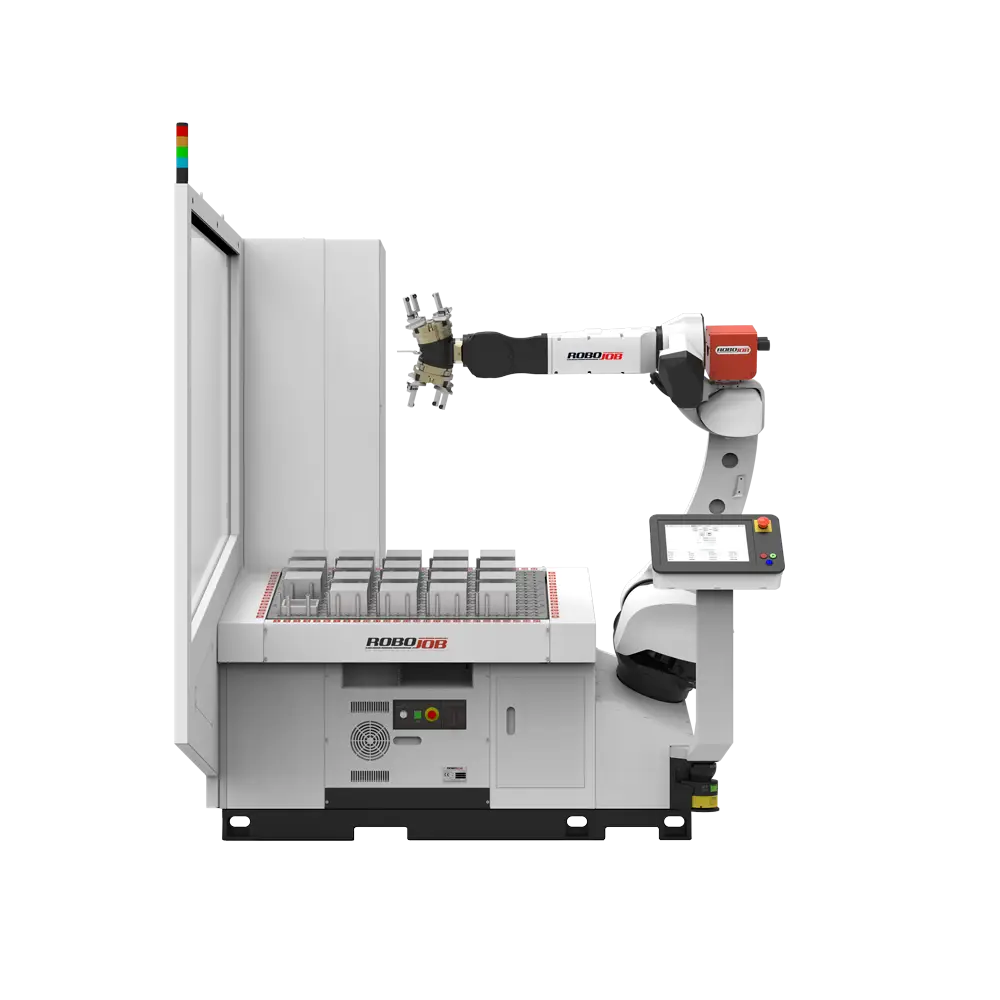

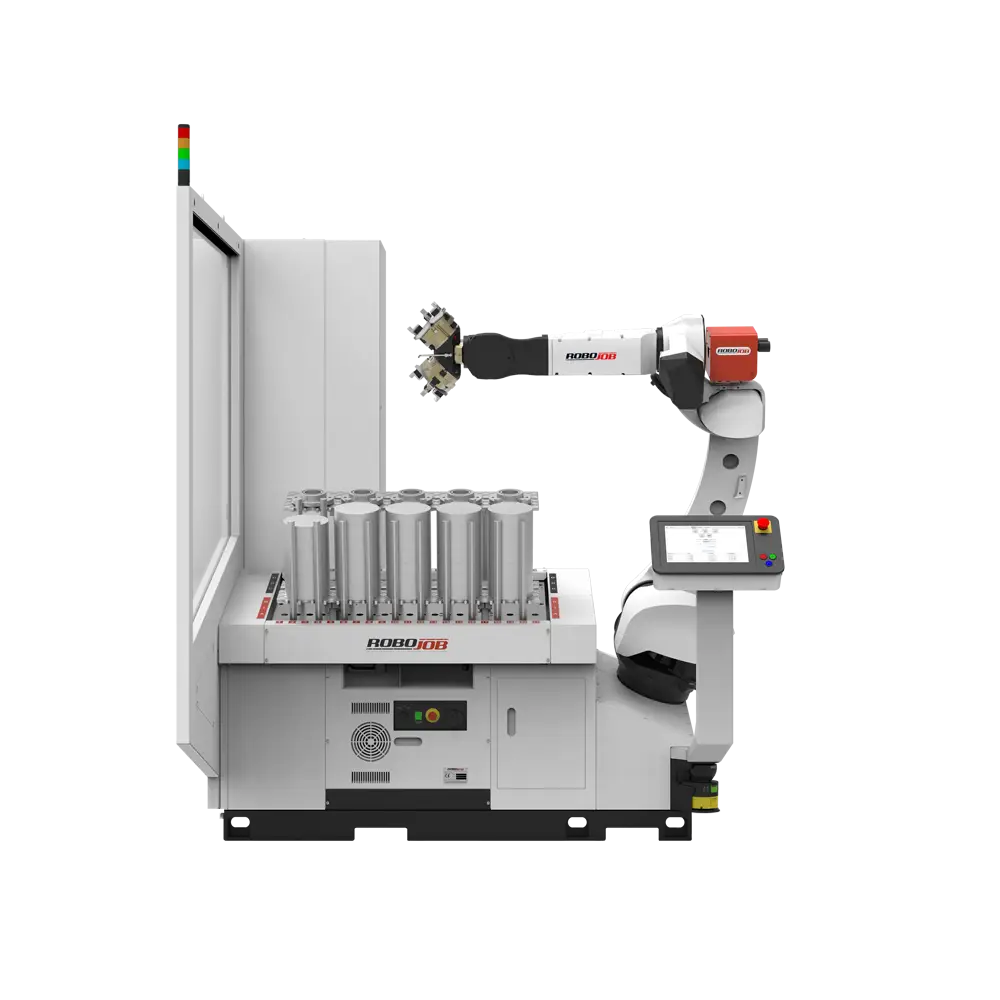

"So we first went ahead with our Turn-Assist, which automatically loads and unloads lathes and in the meantime there are already 3 models of this. In addition we have also constructed 2 standard solutions for the loading and unloading of milling machines: the Mill-Assist Essential and the Mill-Assist Conveyor. And of course we are continuing to work on a series of extensions and options, of which again we have presented 5 new ones at MTMS."

After a steady growth in 2011 and 2012, the train now seems to be up to full speed. What is it that makes RoboJob do it so well? "I think this is due in large part to the fact that we ourselves come from the machining industry," says De Roovere. "Not as a machine manufacturer, not as a different type of supplier, but really from the machining branch. Then you just know how to do your job, what is happening on the floor, and what is important there. The robot is intended as an aid for the people who should be able to perform their work in an efficient and pleasant manner. Hence the word 'Assist' in each of our solutions. All this practical experience is also continually being applied in our products. Those products should be compact, intuitively very quickly adjustable, and also flexible so that you can go in a great many directions with just one automation. And in addition it’s just in every detail of the product: the set-up so that everything remains visible; not only the flexibly adjustable feed table but also your complete machine park. The practical but industrial quality so that the system requires little to no maintenance. Flexibility, efficiency, output, compactness,. .. It's in so many things, often little things that make it completely unique and user friendly.”

RoboJob controls its sales in the Benelux together with renowned partners, but now it also has partners outside the Benelux: Finland, Sweden, Norway, Denmark, Germany, Switzerland, the United Kingdom, Australia and New-Zeeland. In addition, there are a lot of dealers and agents of the TOP brands under the CNC machine manufacturers. "Indeed, and we are quite proud of that," testifies De Roovere. “That such brands somehow or other link their reputation to that of RoboJob, testifies to their belief in us."

Before this summer RoboJob hopes to finalise the two hundredth installation. The RoboJob products appear to be springing up like mushrooms everywhere in Europe. “And that has a lot of consequences for our organization: each installation not only has to be executed, but on top of that we also want to provide top service to our end customers. That’s why we’ve expanded our installation team, and we also certify our international partners, so that they have the necessary know-how and experience to properly complete such an installation” says De Ceuster. "We have also recruited new service engineers in order to support our customers even better."

Also the future seems to be already assured because together with a young and ambitious team, the 3 sons of De Roovere have also joined the company. “Correct,” says a very proud father, “Peter is an ICT Industrial and Civil Engineer and step by step he is taking over responsibility for the entire software package, supported by other young talents with whom he was also at university. Yoeri and Jelle are twin brothers, each with their own talents and skills. Yoeri is an Industrial engineer and responsible for the Installation team and the Service department, and as Commercial Engineer, Jelle is in charge of the international story, wherein he looks for the right partners in our neighbouring countries and also instils them with all the know-how to sell our products there. But of course it doesn’t just stop with the family. We try to attract the right people for the right job. To a man they are young, motivated people each with their own talents and skills. Together they make a fantastic team!”

Are champagne corks going to be popping at RoboJob this year? “Not immediately, Belgium is a beer country and now and again we just enjoy a pint. We have to keep our feet on the ground and continue to work hard,” says De Roovere. “Perhaps it's our Belgian nature: we remain humble, we continue to work hard, but we enjoy our work. Those are the values that I not only want to transfer to my sons, but to our entire company,” concludes De Roovere.