In recent years, CNC automation experienced a huge growth. Since the difficult years that the machining industry has experienced since the start of the economic crisis, companies have increasingly been looking out for solutions that could increase the flexibility of the industry, and which could also improve the profitability of the machining industry. Market leader RoboJob originated from these difficult market circumstances: sister company Aluro CNC was facing, like many other suppliers in Western Europe, a decline in the number of orders, as well as in the batch size of these orders. Moreover, CNC operators are still hard to find today, and personnel costs have increased tremendously for the last 10 years. An internal study at Aluro CNC found that the operators were too much engaged in physical labour, and too little in 'creative' tasks, i.e. the programming of CNC machines. Aluro CNC started looking out for an automation partner that offered flexible, standardized automation products, which could be programmed quickly, but was disappointed not to find any solution that met its criteria. At that point, RoboJob-founder and CEO Helmut De Roovere decided to develop the solution himself. With over 25 years experience in engineering, he had the necessary technical background to build user-friendly and robust machines of flawless quality. Moreover, in Luc De Ceuster he found an ideal business partner, given his many years of experience in software development.

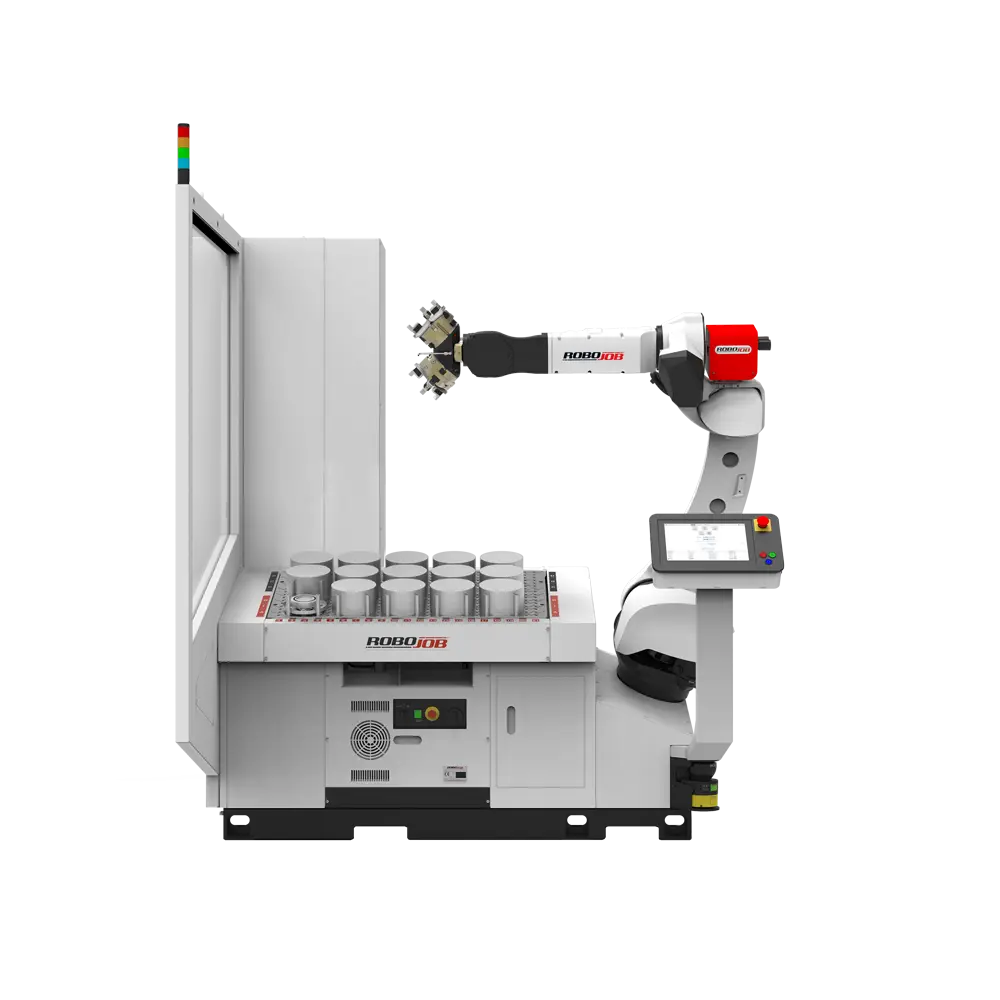

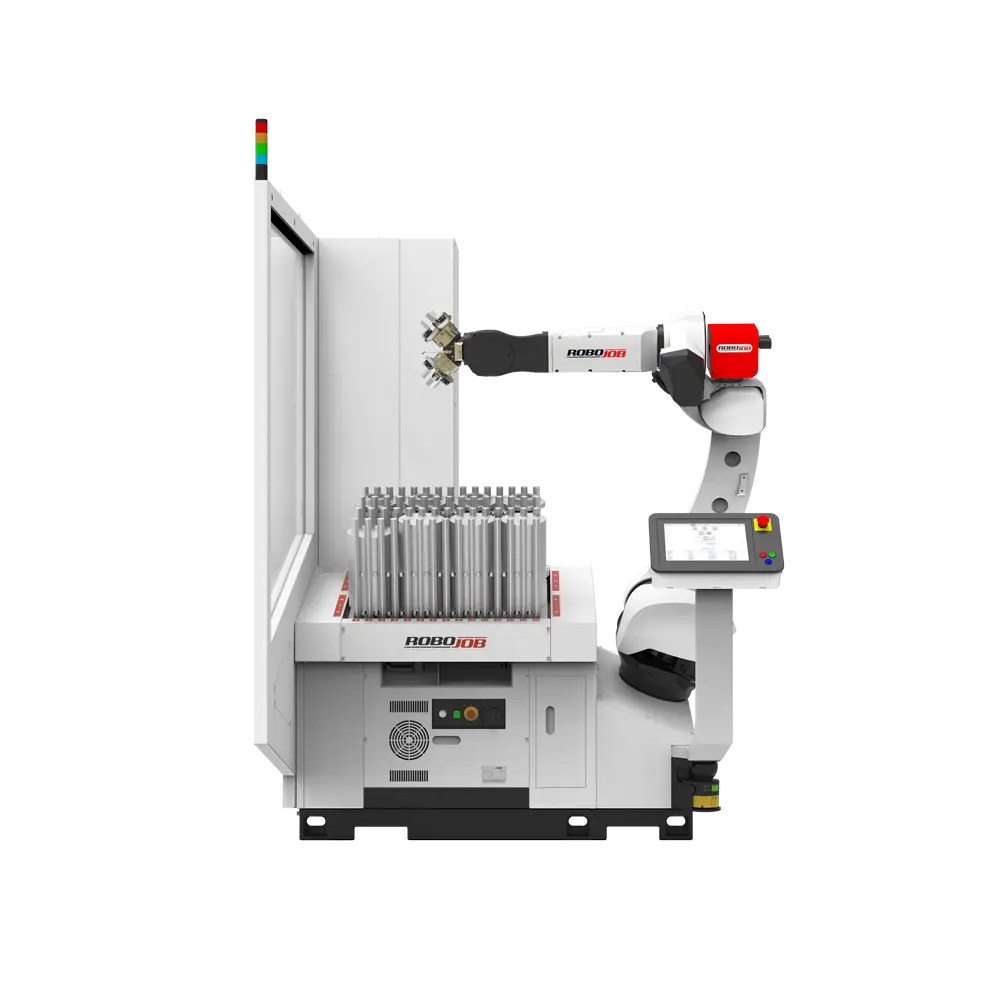

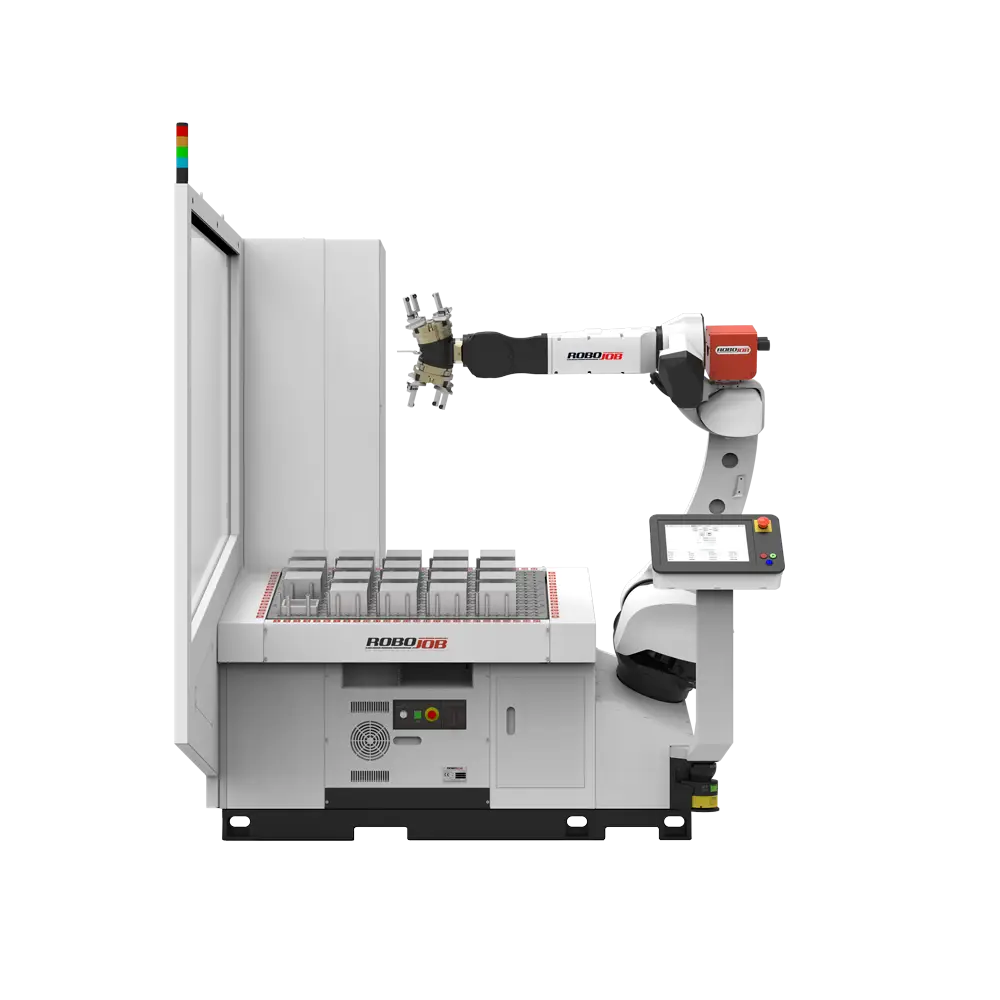

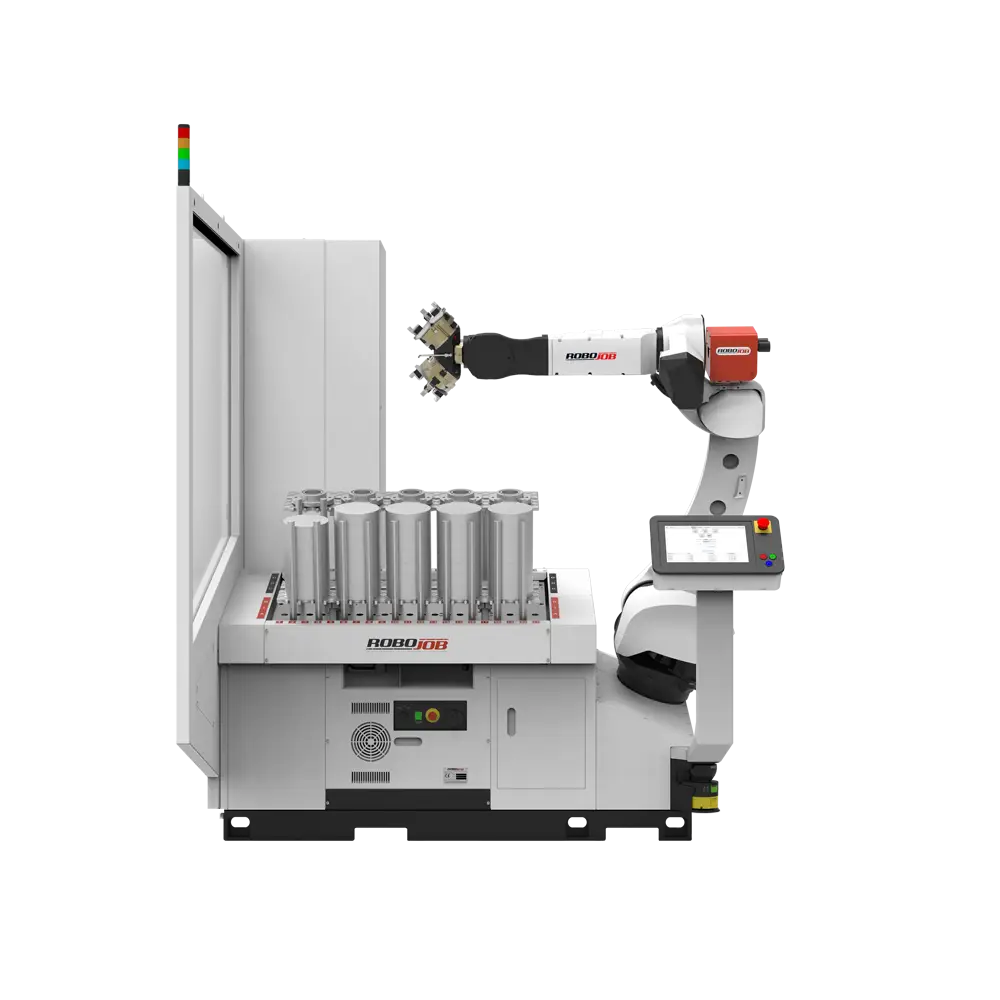

RoboJob was born and in 2011 – after four years of intensive development and testing – it marketed its first standard product: the Turn-Assist. Another four years later, another two standard products were added to the product portfolio: the Mill-Assist Essential and the Mill-Assist Conveyor. Over the years, several extensions and new functionalities were also added. After all, standing still means going backwards. But with each new development, there has always been one steady element: the robot. However, this robot has undergone so many changes that today, we can speak of a turning point: and this is why RoboJob is now launching its new robotic technology.

A robot is a robot, isn’t it? "You would really think so," De Roovere explains. "At first sight, this is also true. RoboJob buys, like many other suppliers, its robots from Fanuc. Fanuc is generally known for its outstanding quality and its robust, industrial reliability. This is why their robots have been doing a wonderful job for over 15 years in the automotive industry, where they are running 24 hours a day. 7 days a week. But before our robots arrive at our customers, a lot of extra technology is added to so that they can also be applied in the machining industry. In fact, a great deal of flexibility is expected of them, as well as accuracy. And to be able to meet those requirements, we need to integrate additional functionalities in terms of hardware and software."

Flexibility

This is why many additional elements are added to the hardware of the robot. A red pneubox is added, so that an operator can quickly and easily adjust the clamping force of the grippers. "On a piece of plastic you can not put the same pressure as on metal. You would just squeeze the piece," De Roovere explains. "This seems very simple, but today we offer the only solution on which you can adjust this so easily."

The larger part of the adjustments however are done in the software: one can easily adjust the speed of execution of the RoboJob robot, with just one click on the screen. A Start-Stop button is available to pause the robot at any time - for example, to check that a piece is positioned correctly - and to let him continue his operations. Once, again simply with one click. "Just like you can pause your movie or CD. This is makes perfect sense to me that this is a feature anyone should offer, but this is the kind of features that you will not immediately find on any other automation, despite that it’s so obvious to everyone," De Roovere continues.

"Just Like our 'Home' function: this is something you will find on many devices today. Just think of the Home button on a smartphone. Well, this is also the case for our robot: in the unlikely event that something does go wrong, you should be able to simply say, ‘Home’, and let the robot return to its ‘Home’ position. Without you having to use the Fanuc controller, because that would mean a loss of time and efficiency."

All functions that are obvious to anyone, while experience shows that this is not the case for all providers. Just like the RoboJob feature that indicates where there is an alarm. Most providers do indicate that there is an alarm, but not what is causing it. Then one can start investigating, and a lot of back and forth telephone calls with the machine manufacturer, and with the automation partner. "Obviously we are happy to assist our customers, but we still prefer that he himself is able to quickly and efficiently solve a problem. Without him having to have to come to us. And so we provide him with all the needed information in the software. Paired with our SMS or e-mail module, customers can will also be able to keep an eye on their production on their PC or mobile phone. So you can monitor your production from the ski slopes, and make adjustments where necessary."

There is a clear focus to design and develop in function of customer requirements. That RoboJob itself originates from the machining industry, can also be noticed from the standard features that increase the flexibility of the customer: the RoboJob robot can grab a piece at its center, but also outside of its the center (eccentric). Once again, a unique feature in the market. One can also discharge work pieces from the sub spindle, and work pieces can be loaded and unloaded at a certain angle or rotation. The operator can also easily customize the loading strategy so that a work piece is pressed against the stop, or to operate without a stop. Bar break functions, setting up your own grippers in the software, measuring after X pieces or the increasingly important pre- and post-processes: the list of standard features seems endless at RoboJob.

Accuracy

Accuracy is a very important element in machining, and RoboJob - itself originated from the machining - obviously knows that: the Belgian automation expert has programmed a weight compensation feature into the software of the robot, so that the robot can also load and unload heavier pieces as accurate as smaller pieces. One even goes above and beyond during installation to further increase the accuracy. "One-tenth of a millimeter can make the difference for our customers. This is why we run a calibration upon installation: we have developed our own calibration technology, where the full range of the robot is mapped after it was installed. These data are stored in the software, and the robot uses this data to perform its movements even more precise," De Roovere explains.

Profitability

What perhaps is most impressive, but not visible to the naked eye, is that the RoboJob software has been designed in such a way that all calculations are done while the robot is moving. Thus, every step is carefully considered before, as it were. "Like a chess game," De Roovere notices. "As a user, you will of course not notice this, but this does mean that there is not a single second that is lost. At the end of the day, what our customers want, is to increase their profitability. That’s what everyone is shouting of course, but as a customer you want be able to rely on a partner who considers every detail, and who does the thinking for you. And that, we can guarantee at RoboJob: every customer who now purchases one of our standard systems, knows that with RoboJob, he has a partner who will do anything to increase his profitability."

Smart. Simple. Strong service.

As the 'tagline' of RoboJob - Smart. Simple. Strong Service. - indicates, there is a continuous in-depth reflection at RoboJob to offer the operator intelligent software, which should still be easy to operate. A remarkable aspect is that all functions are available as standard features, and that they are therefore offered to each individual customer. "Indeed. After all, every customer is king, and each one of them has high expectations, which we want to meet as a partner. And if something is not possible today, with our software updates we can make it happen tomorrow. After all, we continuously work on further improvements, from which every customer can benefit," De Roovere concludes.

RoboJob officially launches its robot technology with a new "look and feel" that will officially be presented at the MTMS tradeshow in Brussels. You will find RoboJob from 25 to 27 March 2015 at booth 10 of the MTMS tradeshow in Brussels Expo. You can find all the RoboJob products, technical information and prices at the RoboJob booth.