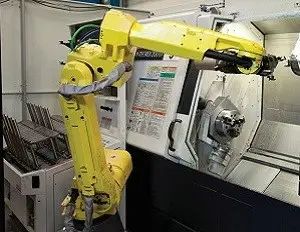

A robot that loads and unloads a CNC turning or milling machine: it is no longer a novelty in machining. The robots seem to be rising from the ground like mushrooms. RoboJob has taken on a leading role with its contribution to the profitability of the machining companies. Meanwhile, the outlook seems to grow slightly more positive again for an industry that has been facing difficult times in recent years in Belgium, the Netherlands and other Western European countries. But to maintain these slightly improving conditions and to continue to improve, it’s important to stay ahead. Also Eastern European countries will not be missing out on automation.

"We are of course happy to see that many machining companies now recognize that automation is a possibility for them, and that it can make a significant contribution to their profitability. But to stay one step ahead of the Eastern European competitors, we must also look ahead, and further optimize these automated processes." These are the words of Helmut De Roovere, co-founder and CEO of the Belgian company RoboJob. De Roovere stood at the cradle of the Belgian expert in automatic loading and unloading of CNC machines, which meanwhile has grown into the market leader in the Benelux and which is also active in several other Western European countries. And De Roovere also has a vision for the future.

"CNC automation does not have to stop with automatic loading and unloading of CNC machines. This is indeed a major step forward, and it allows the operator to focus on those tasks that he really enjoys doing: programming CNC machines or optimizing internal processes. And it’s just for the latter where there is still a lot of work that needs to be done. Fortunately, we see that this is exactly what many of our customers are doing today: they increasingly approach us with the question of what robot can do next. And there’s a lot that he can do."

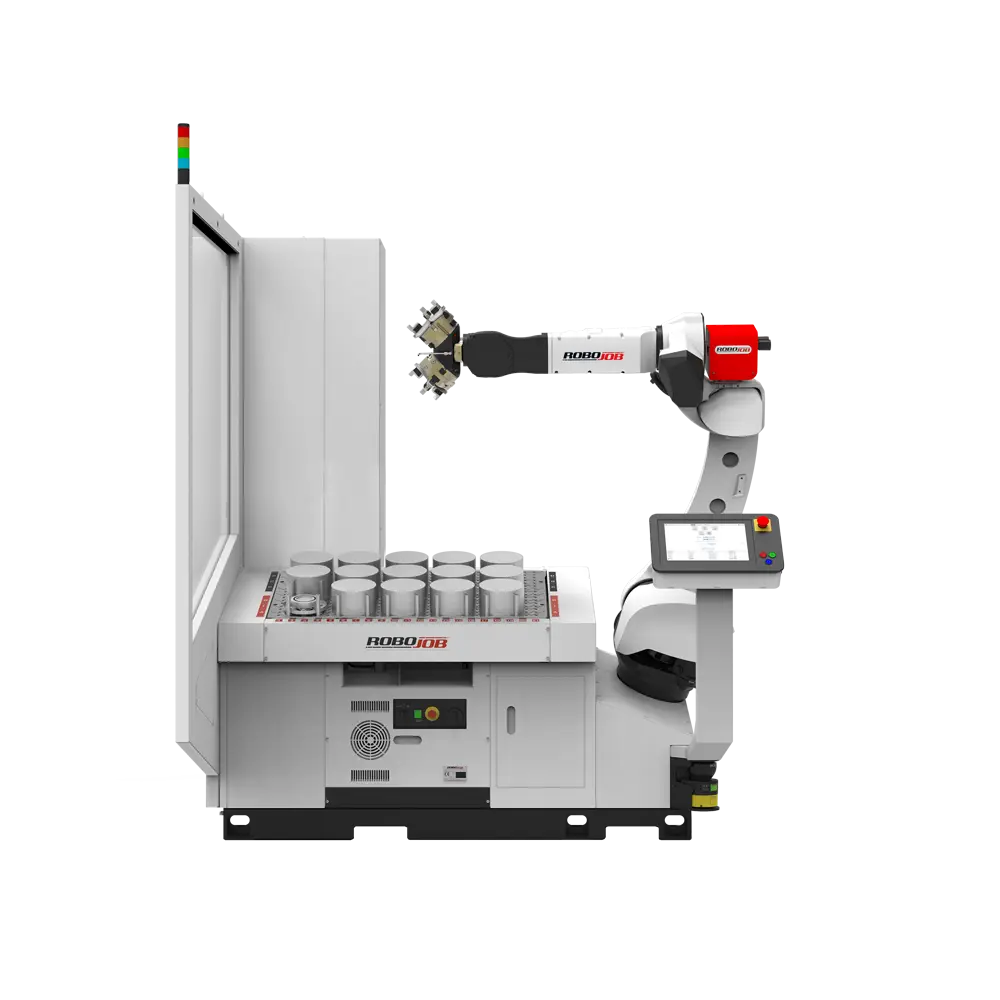

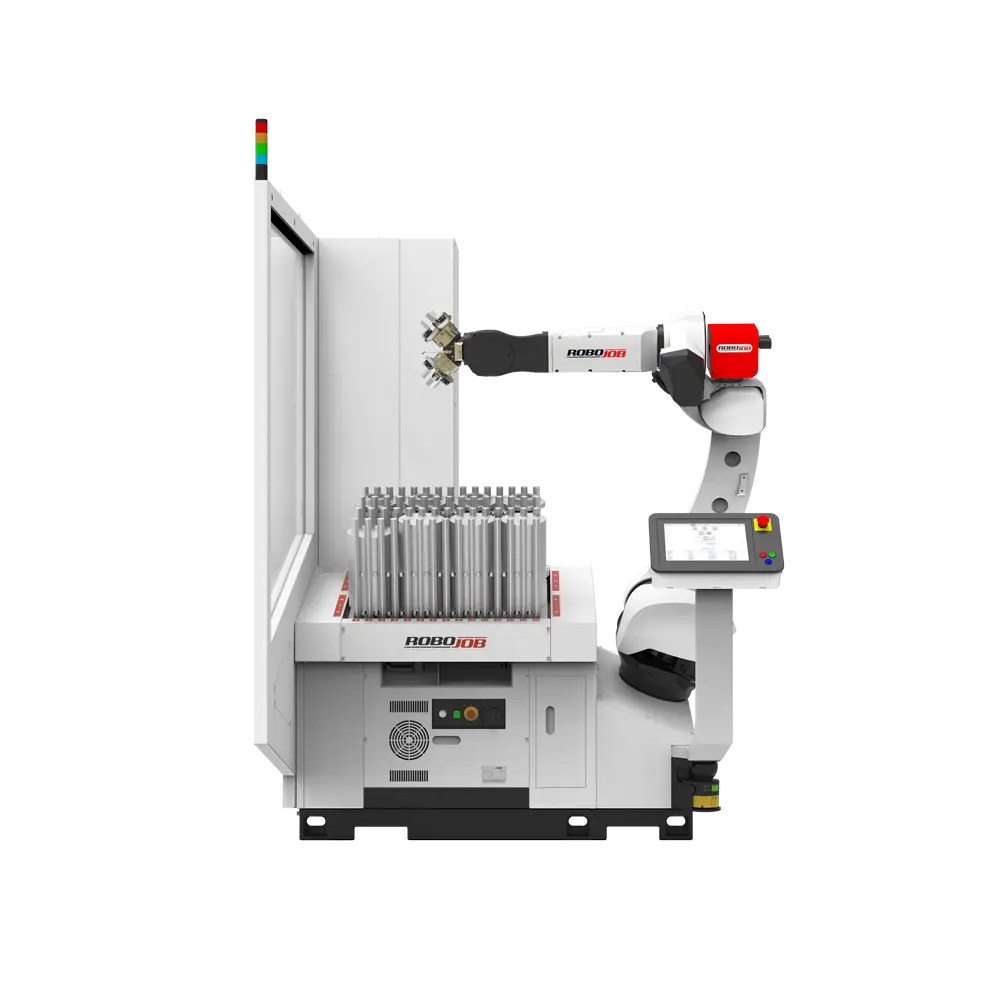

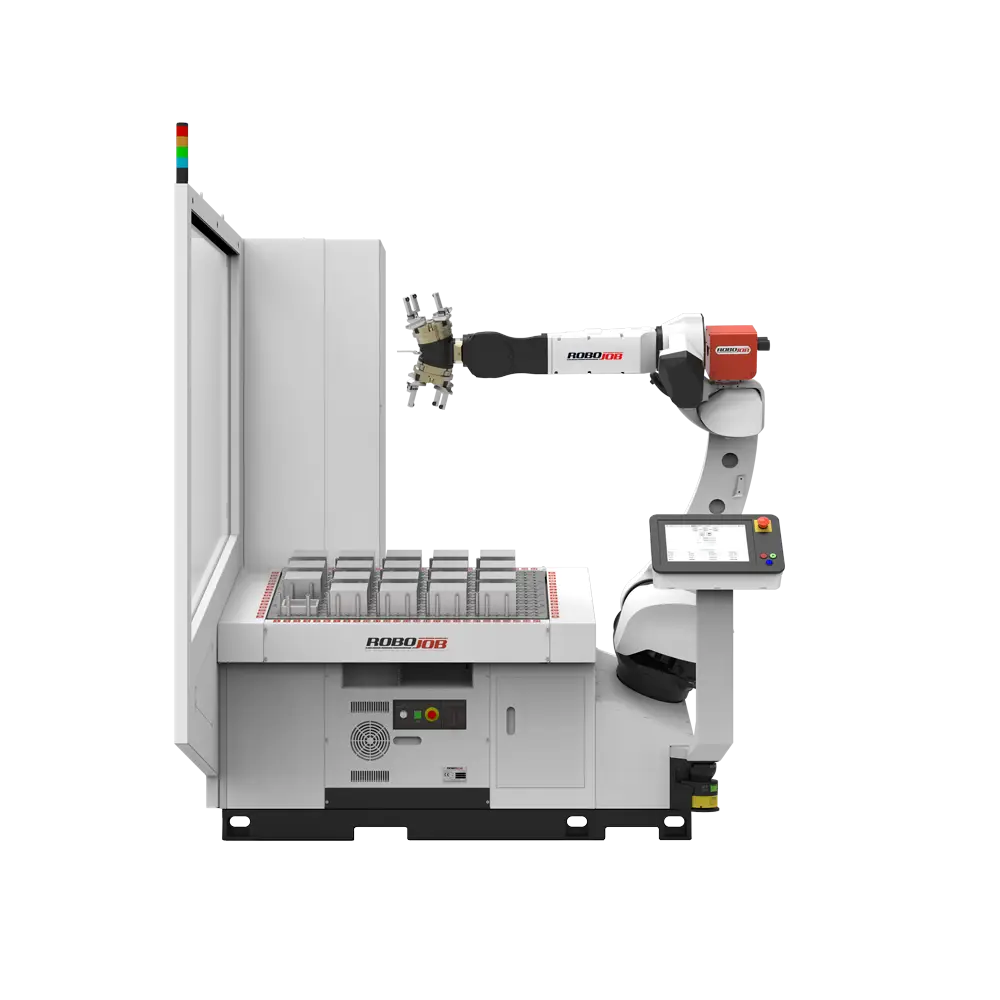

Depending on the cycle time, the robot has a few tens of seconds to several minutes to execute other tasks. Currently, this time is ‘pausing time’: the robot is just waiting until he gets the signal that a piece was finished and he can take it out of the CNC machine to immediately put in another piece. RoboJob now makes it possible to easily indicate in the Turn-Assist software which should be these ‘pre- and post-services’: with only a few clicks, the operator can determine exactly what the robot must do: to wash a finished piece, punch in a serial number or to deburr a finished piece. When the ‘PALLET-UNLOAD’ is available, the robot can also prepare a pallet for a new layer of finished pieces, for example by positioning a piece of cardboard between the layers. Naturally, the necessary hardware equipment should also be available to do so.

The software has been designed in such a way that the operator can determine this quickly and easily. Moreover, these tasks can be saved with a specific name so that the next time, they can easily be recalled and time is won again.

"It’s not just about time savings in the production process of the robot, but also for the operator himself," explains De Roovere. "The operator is and will always be the essential link in the chain, because without an operator, the robot will not keep on working. So we do everything to make life as easy as possible for the operator, and to alleviate the workload and to restore calm in the workshop."

Meanwhile, RoboJob has already made these newly developed standard functions available for several customers, simply with a software update. "That is indeed a great advantage: we do not need to shut down the plant at a customer to enable new features," says De Roovere. "With a USB key, the software update is installed quickly, and our customers can immediately resume their activities. With the major difference that from that moment, suddenly a lot more can be done," De Roovere concludes.

Exactly which pre- and post-services are now available as standard features, can be discovered by yourself. You will find RoboJob from 25 to 27 March at Booth 10 at the MTMS Tradeshow at Brussels Expo. You can find all the RoboJob products, technical information and prices at the RoboJob booth.