With a lengthy history in technical products, system solutions and services, Oltrogge is the strategic partner for over 15.000 customers. It is also the exclusive dealer for the Mazak CNC lathes and milling machines for large parts of Nordrhein-Westfalen and Niedersachsen. And the company is also very well aware of changing market conditions. Mr. Hartmut Gaese, Division Manager Machinery at Oltrogge & Co. KG, is convinced that user-friendly and flexible automation solutions will open up possibilities for his customers, since they are on the look-out to increase their flexibility as well as their profitability.

“Like elsewhere in Western Europe, our customers have also undergone changing market conditions. They have experienced more competition from Eastern European machining companies, and our customers’ customers are constantly looking for ways to cut costs, improve delivery times and still achieve premium quality. Our customers realize that they will need to step up if they want to maintain their competitive strengths. They will need to grow more flexible, if they want to continue to grow in turnover, while improving their profitability at the same time. What they don’t always realize just yet, is how to address these challenges,” Mr. Gaese continues, “and that is where we enter the picture. Our customers rely on our 150 years of experience to find the solution for them. And we have. Which is why we’ve invited our customers for a two day workshop to share our findings with them.”

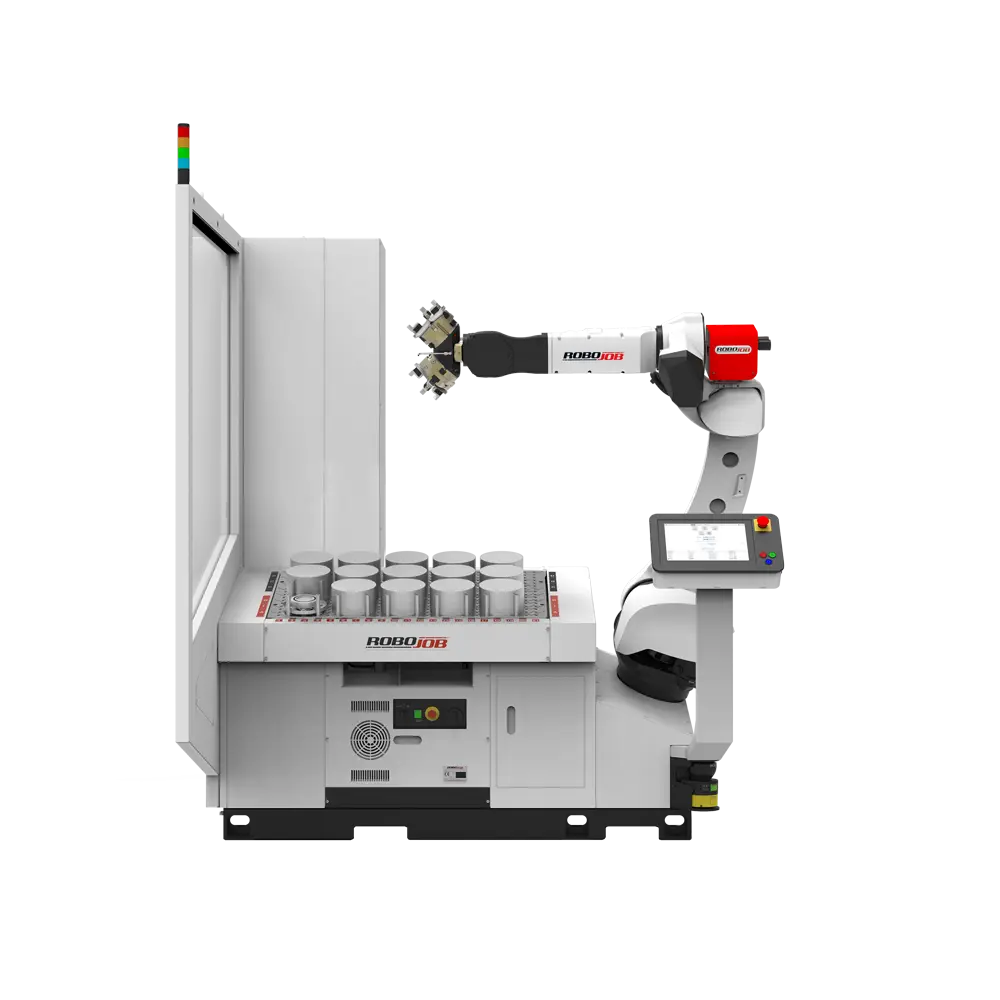

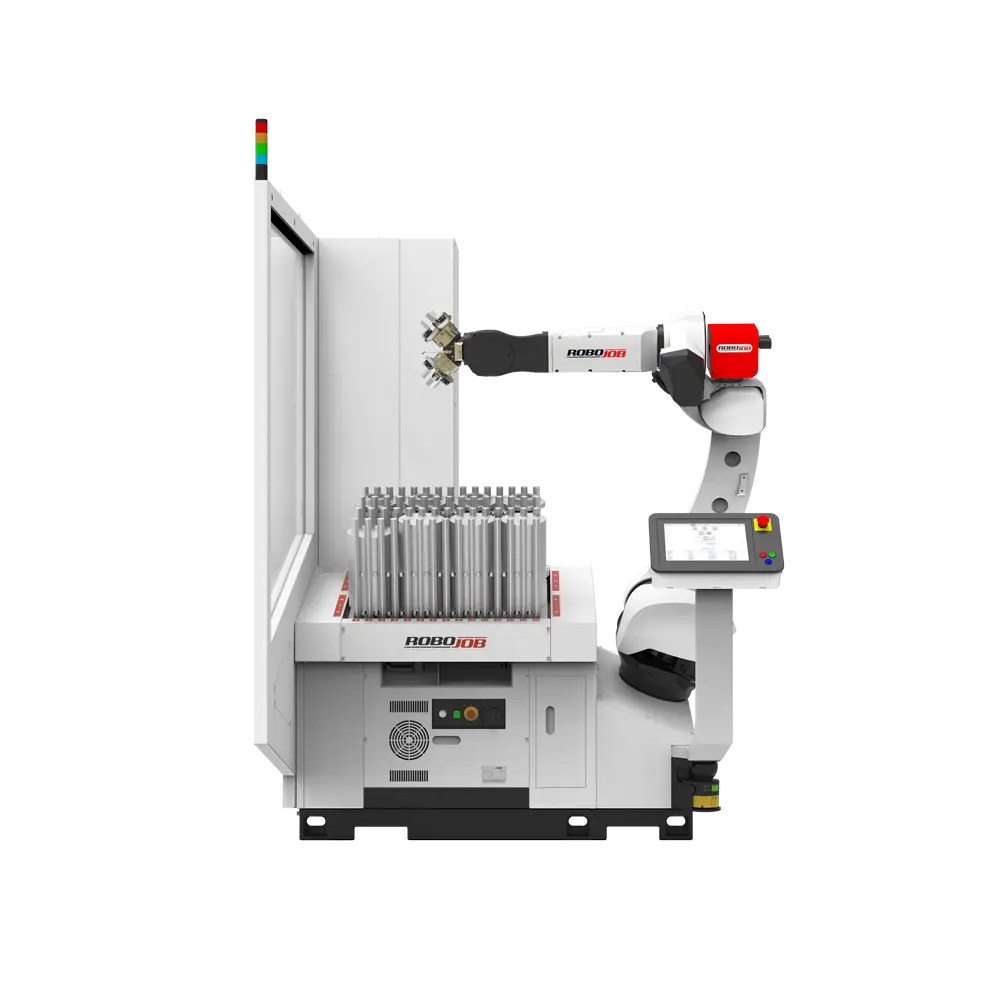

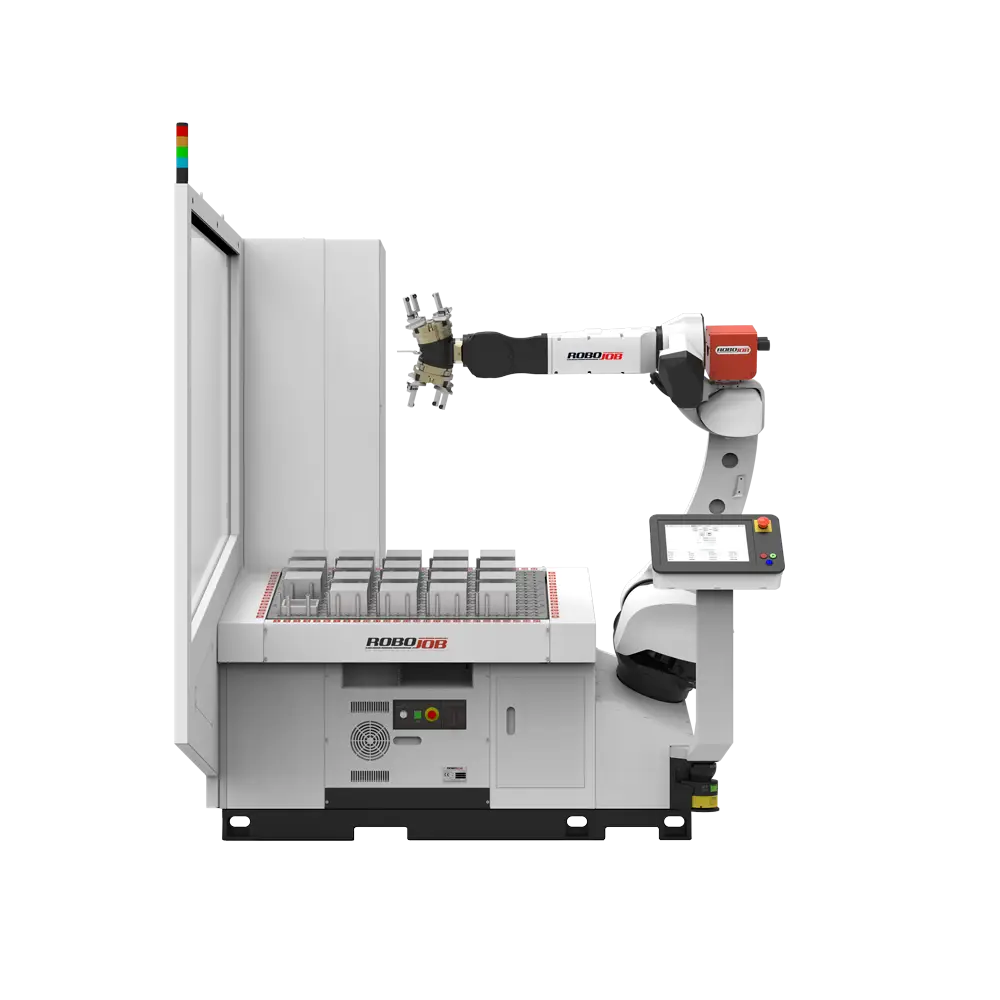

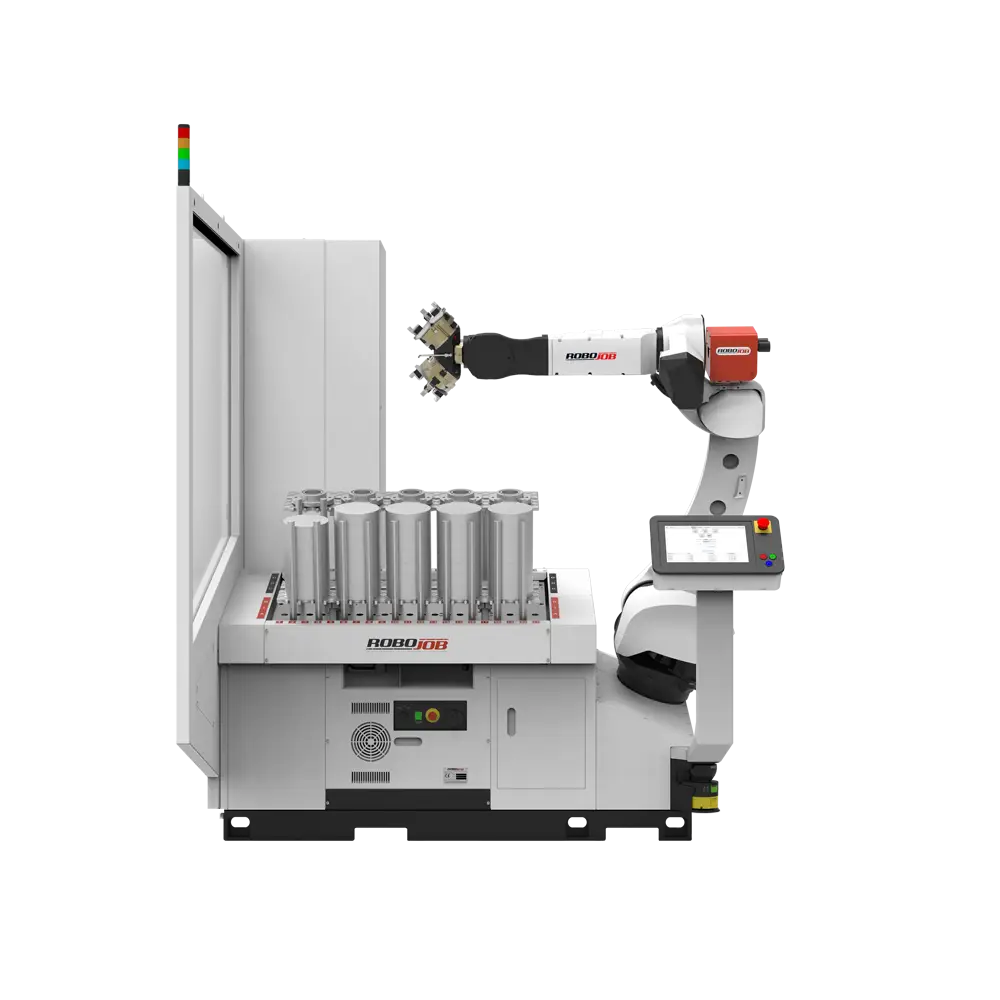

The solution lies with RoboJob’s Turn-Assist and Mill-Assist. These are user-friendly and flexible automation solutions to load and unload turning and milling machines. Unlike many other automation solutions, Belgium-based RoboJob specifically developed these automation products for small and medium-sized series. And equally important, they were developed from RoboJob’s background in machining.

Based in Belgium, RoboJob was founded in 2007 by engineers Helmut De Roovere and Luc De Ceuster. With over 25 years’ in manufacturing and over 40 years’ experience in machine building, RoboJob can rely on all the needed know-how to build extremely user-friendly standard solutions that can significantly increase gross margins in the machining industry.

The Turn-Assist and Mill-Assist are integrated solutions which enable the automatic loading and unloading of turning and milling machines. Both systems can be used for a wide range of dimensions (standard ø 5 to 400 mm) and weights (up until 700 kg).

Oltrogge & Co. KG has now invited its customers for a workshop around automation. Together with RoboJob, Oltrogge will be providing all the needed insights in today’s market challenges, and how automation solutions can help to address these challenges in an effective manner.